- [M] Diameter (Screw Thread) Nominal

- 3

- 4

- 5

- 6

- 8

- 10

- [L] Length(mm)[10-60/0.1mm units]

- Material

- Steel

- EN 1.7220 Equiv.

- Stainless Steel

- EN 1.4301 Equiv.

- Surface Treatment

- Strength Class (Steel)

- 10.9

- Strength Class (Stainless Steel)

- D Part Dia.(Ø)

- 4

- 4.5

- 5

- 5.5

- 6

- 6.5

- 8

- 10

- [F] Length (Screw Thread)(mm)[3-24/0.5mm units]

- CAD

- 2D

- 3D

- Uppskattade leveransdagar

- Alla

- Inom 7 arbetsdagar

Reamer bolts / hexagon socket / length configurable / tolerance g6, h7 / 10.9, A2-50

Artikelnummer:

kandidater hittades.Skiss och specifikationstabell

Back to the Category Shoulder Bolts/Shoulder Screws/Screws with Shoulder

Available dimensions and tolerances can be found under the tab More information.

| Type | D Tolerance | Material | Hardness | Strength Class |

| GDMSB | g6 | EN 1.7220 Equiv. | 33~38HRC | 10.9 |

| GDSMSB | EN 1.4301 Equiv. | - | A2-50 | |

| HDMSB | h7 | EN 1.7220 Equiv. | 33~38HRC | 10.9 |

| HDSMSB | EN 1.4301 Equiv. | - | A2-50 |

Further specifications can be found under the tab More Information.

| Part Number | - | L | - | F | - | M |

| HDSMSB6.5 | - | 30 | - | F12 | - | M5 |

Alterations for fitting bolts/shoulder bolts

Here to the highly configurable shoulder bolts

Alterations for shoulder bolts

Here to the highly configurable shoulder bolts

Shoulder bolts selection details

- Drive: hexagon (external hexagon), hexagon socket, Kreutz slot, knurled head

- Strength classes: 8.8, 10.9, A2-50

- Threads: M2.5, M3, M4, M5, M6, M8, M10, M12, M16

-Shaft length: 3 to 150 mm

- ISO tolerance: g6, h7, e9

- Surface treatment: burnished, nickel-plated

- Materials: stainless steel, steel

Description/Basics

The screwed connection is one of the most commonly used methods among the disconnectable connections. Due to your tightly tolerated shaft, shoulder bolts, also called shoulder screws, have various advantages over conventional screws.

The precisely manufactured shaft of the shoulder bolt can be used for various purposes. The shaft of the shoulder bolt can be used for precise position fixing and centring, as well as guidance or assembly. Similar to a straight pin, the shoulder shaft of the shoulder bolt can also serve to absorb transverse forces or shear forces.

Example of a shoulder bolt or shoulder screw with shoulder

Shoulder bolts are well suited to store rotating components and at the same time to connect them with each other by screwing them together. The shoulder bolt forms a positive-locking and friction-locking connection with the precisely tolerated shoulder. The low surface roughness enables good gliding properties for lifting and rotational movements.

As a rule, shoulder bolts are set off and therefore have a larger shoulder diameter than the thread. MISUMI also offers shoulder bolts with the same diameter in its product range, such as the RMB and RMBF variants.

Shoulder bolts, which are also known as Fulcrum pins, can take on several tasks at the same time with their different head geometries. The MISUMI bolts are available with flat and very flat heads. The main advantages of flat-headed screws with a socket are weight and space savings compared to a conventional head shape. With the flat head of the shoulder bolts with attachment, up to 6.5 mm of the head height can be saved.

The MISUMI shoulder bolts are similar to DIN 923, DIN 7968, and ISO 7379. However, MISUMI offers these with a configurable length of the shoulder and the thread.

MISUMI offers shoulder bolts in various strength classes.

Since some shoulder bolts are equipped with a flat head, the strength values deviate from the standard values. Therefore, note the values that are assigned to the respective shoulder bolts. This can be found under the Section Basic Properties or under the tab More Information.

Areas of Application

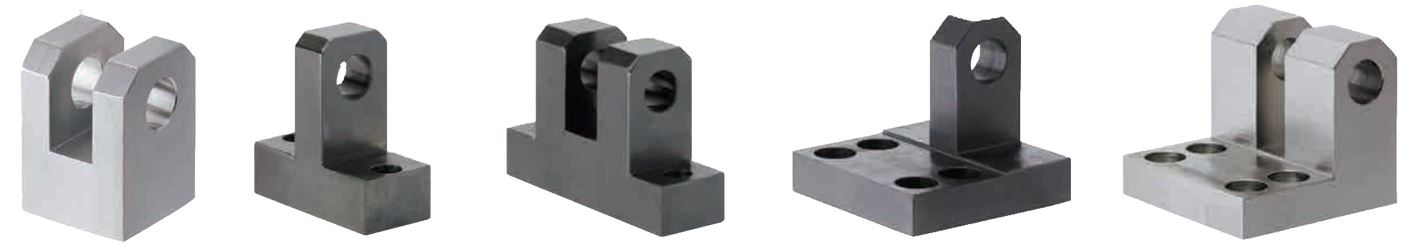

Due to their versatility, shoulder bolts are indispensable in various industries of mechanical engineering and plant engineering. Shoulder bolts are provided for the connection and guidance of joining parts. The shoulder bolts are also a popular choice in various industries for receiving return rollers or belt pulleys on rolling friction bearings. The precisely tolerated shaft of the shoulder bolt can also be used for short strokes, as well as a type of guide column. This is often used in punching tool construction, since the shoulder bolt can also limit the stroke. The tightly tolerated shaft of the shoulder bolt enables very precise positioning and centring of the components to be joined. Shoulder bolts are essential for connecting rod end bearings and links. If other designs are necessary for the connection, hinge bolts can also be used instead of a shoulder bolt.

Materials

MISUMI’s shoulder bolts are available in steel and stainless steel. Information about the degree of hardness can be found under the Section Basic Properties (see above).

Coatings

MISUMI’s fitting shoulder bolts made of steel can be selected burnished or nickel-plated in order to protect them as best possible from corrosion. Stainless steel shoulder bolts are uncoated because the stainless steel provides sufficient protection against corrosion.

Dimensions

The shoulder bolts from MISUMI can be selected from a thread size of M2.5 up to a thread size of M16. The shaft diameter of the shoulder bolt ranges from 4 mm to 20 mm and can be selected with the ISO tolerances g6, h7, e9. The shaft length can be configured from 3 mm up to a length of 150 mm in 1 mm increments. Options [LTC] or [LC] allow some shoulder bolts to be configured in 0.1 mm increments.

The MISUMI shoulder bolt can be configured to generate your individual shoulder bolt. Depending on the application, you can therefore deviate from the typical standard sizes of the fitting screw.

Instructions for use

Strength classes

The strength class gives the tensile strength [R m ] and yield strength [R e ], or expansion limit [R p-0.2] of the screw.

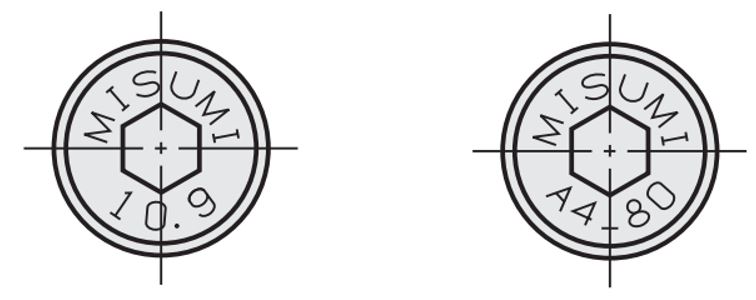

Shoulder bolts that are subject to a strength class are often marked by marking the strength class on the screw head. For some screws, the reference to the strength class is missing. In such cases, please refer to the screw data sheet (see Basic Properties).

The screw strength class is an indication of the tensile strength and the expansion limit of a screw. The higher the specification of the strength class, the higher the tensile strength and expansion limit. In principle, a distinction is made between steel and stainless steel (stainless steel).

Stainless steel screws are marked with the letters A, C and F (e.g., A2-50). Steel screws are marked with two numbers, separated by a dot (e.g., 8.8).

The tensile strength and elongation limit can be determined based on this information. Which of the two values and safety number are used for the further calculation of the screws depends on the applied load case.

Example of a strength marking

Tensile strength steel

In order to determine the tensile strength of the screw material of a steel screw, the first number of the strength specification is multiplied by a factor of 100.

Example: 8.8

R m = 8 x 100 N/mm 2 = 800 N/mm ²

The expansion limit of the screw material is the resistance value that can be applied to the material without permanent deformation. Thus, the screw can return to its original length after this stress (elastic range).

If the elastic range is exceeded, there is a permanent (plastic) deformation, which can end in a tear/fracture of the material upon further stress.

To determine the value, both values of the strength specification are multiplied with each other and additionally by a factor of 10.

Example 8.8

R p-0.2 = 8 x 8 x 10 N/mm ² = 640N /mm ²

Tensile strength stainless steel

For stainless steel screws, the strength specification begins with the specification of the material group used.

The most common stainless steel screw is the A2 stainless steel screw, which is manufactured from (colloquially speaking) V2A material. In this example, the A2 screw is made of austenitic stainless steel.

Ferritic stainless steel screws are often marked with a [F] at the beginning and martensitic stainless steel types with a [C].

Unlike the steel screws, the second value of the strength specification is multiplied by a factor of 10 for the stainless steel screws in order to determine the tensile strength of the screw material. The expansion limit [R p-0.2] must be determined in tabular form based on the expansion limit of the raw material or the manufacturer.

Example A2-50

R m = 50 x 10 N/mm ² = 500 N/mm ²

Screws without specification of this strength classification have manufacturer-bound values that must be taken from the respective data sheets or manufacturer information. This often occurs with screws with special shape and treatment.

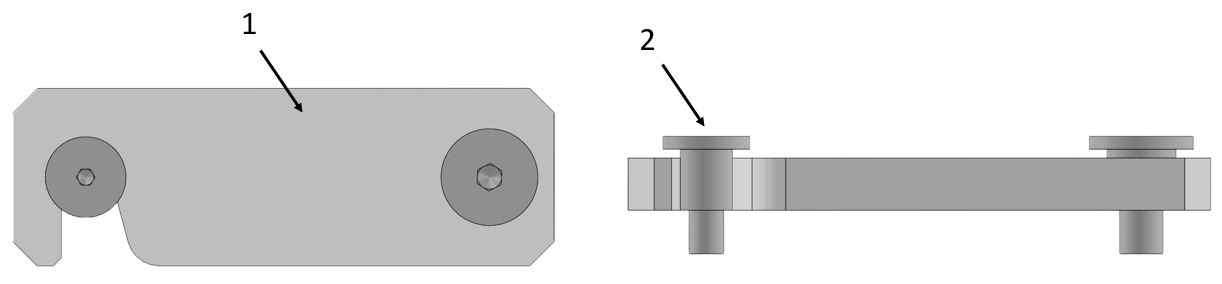

A common application for shoulder bolts in the tool construction industry is guidance and stroke limitation (stopper bolt).

.JPG)

(1) Shoulder bolts as stroke limitation

A shoulder bolt is well suited for the assembly of rod end bearings and links. The tightly tolerated shaft of the shoulder bolt can greatly reduce the play. With conventional hexagon head screws, this application would have significantly more clearance.

.JPG)

(1) Shoulder bolt, (2) washer, (3) spring washer, (4) nut, (5) link, (6) rod end bearing, (7) connecting rod

Shoulder bolts are also often used for installing rollers. The precisely tolerated shoulder of the shoulder bolt is well suited for bearing a roller with integrated ball bearing. The precisely manufactured shoulder bolt reduces the play of the rollers and contributes to good smooth running and durability.

.JPG)

(1) Roller

The MISUMI shoulder bolts with extra flat head are well suited for the use of a swivel plate. The tightly tolerated and flat shaft of the shoulder bolt can minimize tilting and hooking of the swivel washer, resulting in fewer complications.

(1) Link, (2) shoulder screw with extra flat head

Artikelnummerlista

| Artikelnummer |

|---|

Enhetspris (exklusive MOMS)(Enhetspris inklusive MOMS) | Standardavsändningsdatum |

|---|

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

Detaljerad information

Grundläggande information

Försiktighet

- For M=D there is no undercut.Therefore the length of the thread F is longer (approx. 1-2 pitches) and dimension L smaller than stated.

Skiss och specifikationer

Back to the Category Shoulder Bolts/Shoulder Screws/Screws with Shoulder

Overview of the various designs as PDF

| D Tolerance | A | B | C | E | T | L+F Machining Conditions | ||

| D | g6 | h7 | ||||||

| 4 | -0.004 -0.012 | 0 -0.012 | 7 | 2.5 | 1.6 | 3 | 4.5 | L+F≤46 |

| 4.5 | 5 | |||||||

| 5 | 9 | 3 | 2.2 | 3.5 | 5.5 | L+F≤47 | ||

| 5.5 | 6 | |||||||

| 6 | 10 | 4 | 2.5 | 5 | 6.5 | L+F≤59 | ||

| 6.5 | -0.005 -0.014 | 0 -0.015 | 7 | |||||

| 8 | 13 | 5 | 3 | 6 | 8.7 | L+F≤70 | ||

| 10 | 16 | 6 | 4 | 8 | 10.8 | L+F≤72 | ||

| MxP |

| 3x0.5 |

| 4x0.7 |

| 5x0.8 |

| 6x1.0 |

| 8x1.25 |

| 10x1.5 |

| Part Number | L 0.1mm Increment | F 0.5mm Increment | M | Unit Price | |||||||||

| Type | D | GDMSB | GDSMSB | HDMSB | HDSMSB | ||||||||

| GDMSB GDSMSB HDMSB HDSMSB | 4 | 10~40 | 3~9 | 3 | 4 | ||||||||

| 4.5 | 10~40 | 3~9 | 3 | 4 | |||||||||

| 5 | 10~40 | 4~12 | 3 | 4 | 5 | ||||||||

| 5.5 | 10~40 | 4~12 | 3 | 4 | 5 | ||||||||

| 6 | 10~50 | 5~15 | 4 | 5 | 6 | ||||||||

| 6.5 | 10~50 | 5~15 | 4 | 5 | 6 | ||||||||

| 8 | 10~60 | 6~18 | 5 | 6 | 8 | ||||||||

| 10 | 10~60 | 8~24 | 6 | 8 | 10 | ||||||||