- Belt Width(mm)

- 15

- 20

- 25

- [T] Number of Teeth

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- Pulley Shape

- Material

- Aluminum

- Aluminum Alloy 7000 series

- Ultra Super Duralumin Aluminum Alloy

- Surface Treatment

- [d] Diameter (Shaft Bore)(mm)

- 8

- 10

- 12

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 22

- 24

- 25

- 28

- 30

- CAD

- 2D

- 3D

- Uppskattade leveransdagar

- Alla

- Inom 8 arbetsdagar

- Inom 9 arbetsdagar

- Inom 10 arbetsdagar

- Inom 11 arbetsdagar

Timing belt pulleys with keyless bushings / T5 / flanged pulley deselectable / aluminium(Artikelnummerlista: 6-sida)

Artikelnummer:

kandidater hittades.Skiss och specifikationstabell

Back to the Category Toothed Pulleys/Timing Pulleys/Idler Pulleys

Technical Drawing - Toothed Pulleys/Timing Pulleys/Idler Pulleys

Available dimensions and tolerances can be found under the tab More Information.

Basic Properties (e.g., material, hardness, coating, tolerance) - Toothed Pulleys/Timing Pulleys/Idler Pulleys

| dH7 | Max. allowable torque (N⋅m) | D1 | (L) | |

| HTTA ·HTTK | HTTAS | |||

| 8 | 19.6 | 10.7 | 23.5 | 6.0 |

| 10 | 27.5 | 12.7 | 25.5 | |

| 12 | 44.1 | 24.5 | 28.5 | 6.5 |

| 14 | 63.7 | 28.4 | 30.5 | |

| 15 | 80.4 | 30.4 | 31.5 | |

| 16 | 83.3 | — | 33.0 | |

| 17 | 92.2 | — | 33.5 | |

| 18 | 95.1 | — | 34.5 | |

| 19 | 98.1 | — | 35.5 | |

| 20 | 216.0 | 122 | 42.0 | 8.0 |

| 22 | 255.0 | — | 44.0 | |

| 24 | 363.0 | — | 46.0 | |

| 25 | 392.0 | 153 | 47.0 | |

| 28 | 441.0 | — | 50.0 | 8.5 |

| 30 | 500.0 | 230 | 52.0 | |

| 32 | 530.0 | — | 54.0 | |

| Nominal Width | MechaLock inner dia. dH7 |

| T5100 | 10·12·14 |

| T5150 | 20·22 |

[ ! ] Surface treatment may not be applied to the shaft bores.

[ ! ] Flange is installed.

[ ! ] Unless otherwise specified except for teeth and F dimensions, the dimension tolerance conforms to JIS B 0405 Class m.

| Type | Belt Width | [M]Material *1 | [S] Surface Treatment | |||||||

| 10 mm | 15 mm | 20 mm | 25 mm | Pulley | Flange | MechaLock | Pulley | Flange | MechaLock | |

| T5100 | T5150 | T5200 | T5250 | |||||||

| HTTA | ● | ● | ● | ● | Extra Super Duralumin Aluminum alloy | Aluminum alloy | EN 1.1191 Equiv. | Clear Anodize | — | |

| HTTK | ● | ● | ● | ● | Hard clear anodize *2 | — | ||||

HTTAS | ● | ● | ● | ● | EN 1.4301 Equiv. | Clear Anodize | — | |||

*2 Hard clear anodize: film hardness 300 HV or more

| mm | Nominal | |||

| T5100 | T5150 | T5200 | T5250 | |

| A | 11 | 17 | 22 | 27 |

| W | 16 | 22 | 27 | 32 |

| Y | — | 14 | 14 (up to d10) 18 (d12 or more) | 14 (up to d10) 22 (d12 to 22) 23.5 (d24 or more) |

Further specifications can be found under the tab More Information.

Composition of a Product Code - Toothed Pulleys/Timing Pulleys/Idler Pulleys

| Part number | — | Pulley Shape | — | Shaft Bore Dia. |

| HTTA48T5250 | — | F | — | 20 |

Alterations - Toothed Pulleys/Timing Pulleys/Idler Pulleys

| Part number | — | Pulley Shape | — | Shaft Bore Dia. | — | (BMC, etc.) |

| HTTA40T5250 | — | E | — | 18 | — | BMC |

| Alterations | Surface Treatment | Flange Cut | No Flange | Single Flange | |

| Code | BMC·BMR | FC | NFC | LFC·RFC | |

| Spec. | Applies electroless nickel plating on a MechaLock. (Antirusting treatment is applied to screws.) [ ! ] Electroless nickel plating decreases bushing's allowable torque by 20 to 30%. BMC: Not RoHS Compliant (Screw: SCM435 Dacrotized Treatment) BMR: RoHS Compliant (Screw: SCM435 GeoMet Coating) | Lowers the flange by cutting. FC: 0.5 mm Increments [ ! ] No surface treatment is applied on flange circumference. | The product is shipped without swaging the flange. (Flange Included) | The product is shipped by swaging the flanges either on the bushing side (LFC) or the opposite side (RFC). (Flange 1 pc. Included) | |

| [ ! ]FC ≥ (O. D.) +1 [ ! ]FC ≤ F-2 Ordering Code FC43 |  |  | ||

Here to the Overview of Options as PDF.

General Information - Toothed Pulleys/Timing Pulleys/Idler Pulleys

Selection details of toothed pulleys/timing pulleys/idler pulleys

- Material: aluminum, steel, stainless steel (stainless steel), plastic

- Coatings: uncoated, burnished, anodized, nickel-plated

- Profile form: 1.5GT, 2GT, 3GT, 5GT, P2M, P3M, P5M, P8M, S2M, S3M, S5M, S8M, S14M, T2.5, T5, T10, AT5, AT10, 5M, 8M, 14M, 8YU, H, L, MXL, XL, PowerGrip GT3: MR2, MR3, MR5

- ISO tolerances: H7

- Belt width (mm): 4, 4.8, 6, 6.4, 7, 7.9, 9, 9.5, 10, 12, 12.7, 15, 18, 19.1, 20, 25, 25.4, 26, 28, 30, 31, 38,1, 40, 50, 50.8, 53, 60, 74, 76.2, 100

- Belt width (inches): 0.19, 0.25, 0.31, 0.37, 0.5, 0.75, 1, 1.5, 2

- Number of teeth: 10 to 72

Description/Basics

The toothed pulley for mechanical engineering is intended for the transmission of force and torque. Timing pulleys enable a gear ratio of speeds through belt pulleys of different sizes. Timing pulleys are more efficient, durable and significantly more maintenance-friendly compared to chain transmissions.

How much torque and load a timing pulley can transmit depends on the width of the belt. The width of the belt must be calculated. It is recommended to ensure the belt is correctly tensioned. MISUMI already offers the suitable idler pulley and return rollers with integrated ball bearings. For design and design help follow this link.

Different profile shapes of the toothed belts and belt pulleys are responsible for the transmission of power. Depending on the positioning accuracy, the applied torque and the conveying weight, MISUMI offers the fitting pulley. Toothed belt drives are generally used in the industry in three areas:

Positioning: Timing pulleys is often used in 3D printers. A toothed pulley with a semi-circular profile (e.g., GT) is often used for the required position accuracy of a 3D printers. The round shape offers the benefit of little play when the direction changes.

Drive: toothed pulleys are also used for high torque. In most cases, a timing pulley with a rounded trapezoidal profile (e.g., S8M) is used. These are particularly well suited for the transmission of high forces, which occur in drives of various applications in order to drive mechanical components.

Conveying: toothed pulleys can also be used for transporting loads. A straight trapezoidal profile is often used for this purpose (e.g., AT). This toothed pulley shape offers a large surface for loading and transmitting of loads.

Which toothed pulley or timing pulley is the right one for your application depends on the respective task of the toothed belt drive. Different toothed disc profiles have proven themselves for each type of application.

Various bore hole shapes and fastening variants are available for shaft mounting. These allow fastening via set screws, keyways and by means of Mecha locks. Fastening via a clamping sleeve has the further advantage that it allows adjusting the alignment continuously. The MISUMI product assortment has these ready-to-install.

Application Examples - Toothed Pulleys/Timing Pulleys/Idler Pulleys

Application example: idler pulley

(1) Idler pulleys, (2) chain tensioner

Application example: deflection roller

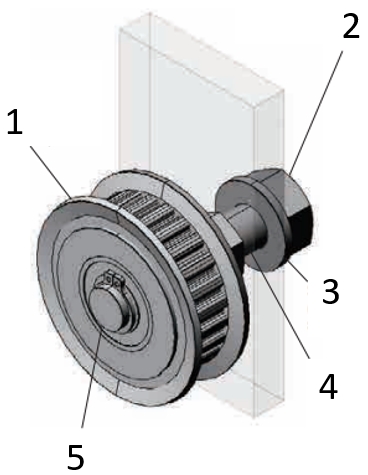

S (1) Toothed pulleys with crimp disc, (2) nut, (3) washer, (4) cantilever shaft, (5) retaining ring

Application example: timing pulleys

(1) Flat head screw, (2) Timing pulley, (3) Timing belt, (4) Screw-on terminal

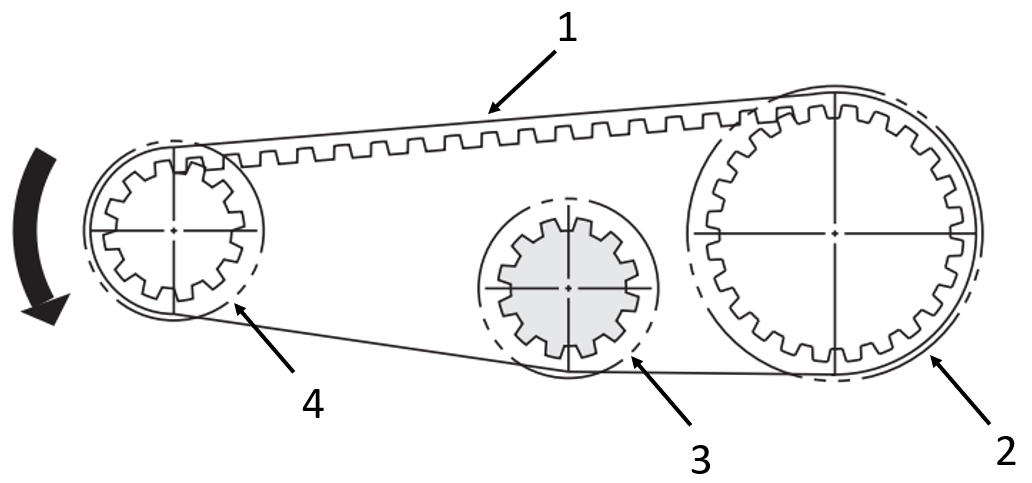

Application example: of toothed belt drives

(1) Toothed belt, (2) driven toothed pulley with crimp disc, (3) idler pulley with crimp disc, (4) driving toothed pulley with crimp disc

Industrial Applications

Artikelnummerlista

| Artikelnummer |

|---|

Enhetspris (exklusive MOMS)(Enhetspris inklusive MOMS) | Standardavsändningsdatum |

|---|

164.11 € ( 195.29 € ) | 10 arbetsdagar |

164.50 € ( 195.75 € ) | 9 arbetsdagar |

165.35 € ( 196.77 € ) | 9 arbetsdagar |

87.93 € ( 104.64 € ) | 9 arbetsdagar |

88.37 € ( 105.16 € ) | 9 arbetsdagar |

88.37 € ( 105.16 € ) | 9 arbetsdagar |

90.27 € ( 107.42 € ) | 9 arbetsdagar |

89.30 € ( 106.27 € ) | 9 arbetsdagar |

90.34 € ( 107.50 € ) | 9 arbetsdagar |

90.79 € ( 108.04 € ) | 9 arbetsdagar |

92.67 € ( 110.28 € ) | 9 arbetsdagar |

93.10 € ( 110.79 € ) | 9 arbetsdagar |

93.10 € ( 110.79 € ) | 9 arbetsdagar |

95.00 € ( 113.05 € ) | 9 arbetsdagar |

94.03 € ( 111.90 € ) | 9 arbetsdagar |

95.41 € ( 113.54 € ) | 9 arbetsdagar |

96.34 € ( 114.64 € ) | 9 arbetsdagar |

96.81 € ( 115.20 € ) | 9 arbetsdagar |

98.17 € ( 116.82 € ) | 9 arbetsdagar |

99.57 € ( 118.49 € ) | 9 arbetsdagar |

87.31 € ( 103.90 € ) | 9 arbetsdagar |

87.75 € ( 104.42 € ) | 9 arbetsdagar |

89.61 € ( 106.64 € ) | 9 arbetsdagar |

90.05 € ( 107.16 € ) | 9 arbetsdagar |

90.05 € ( 107.16 € ) | 9 arbetsdagar |

91.95 € ( 109.42 € ) | 9 arbetsdagar |

91.00 € ( 108.29 € ) | 9 arbetsdagar |

92.12 € ( 109.62 € ) | 9 arbetsdagar |

92.57 € ( 110.16 € ) | 9 arbetsdagar |

94.43 € ( 112.37 € ) | 9 arbetsdagar |

94.87 € ( 112.90 € ) | 9 arbetsdagar |

94.87 € ( 112.90 € ) | 9 arbetsdagar |

96.78 € ( 115.17 € ) | 9 arbetsdagar |

95.81 € ( 114.01 € ) | 9 arbetsdagar |

97.18 € ( 115.64 € ) | 9 arbetsdagar |

98.12 € ( 116.76 € ) | 9 arbetsdagar |

98.60 € ( 117.33 € ) | 9 arbetsdagar |

99.95 € ( 118.94 € ) | 9 arbetsdagar |

101.34 € ( 120.59 € ) | 9 arbetsdagar |

89.00 € ( 105.91 € ) | 9 arbetsdagar |

89.43 € ( 106.42 € ) | 9 arbetsdagar |

91.29 € ( 108.64 € ) | 9 arbetsdagar |

91.74 € ( 109.17 € ) | 9 arbetsdagar |

91.74 € ( 109.17 € ) | 9 arbetsdagar |

93.64 € ( 111.43 € ) | 9 arbetsdagar |

92.68 € ( 110.29 € ) | 9 arbetsdagar |

93.91 € ( 111.75 € ) | 9 arbetsdagar |

94.36 € ( 112.29 € ) | 9 arbetsdagar |

96.22 € ( 114.50 € ) | 9 arbetsdagar |

96.67 € ( 115.04 € ) | 9 arbetsdagar |

96.67 € ( 115.04 € ) | 9 arbetsdagar |

98.55 € ( 117.27 € ) | 9 arbetsdagar |

97.59 € ( 116.13 € ) | 9 arbetsdagar |

98.97 € ( 117.77 € ) | 9 arbetsdagar |

99.91 € ( 118.89 € ) | 9 arbetsdagar |

100.37 € ( 119.44 € ) | 9 arbetsdagar |

101.74 € ( 121.07 € ) | 9 arbetsdagar |

103.13 € ( 122.72 € ) | 9 arbetsdagar |

90.68 € ( 107.91 € ) | 9 arbetsdagar |

91.11 € ( 108.42 € ) | 9 arbetsdagar |

Detaljerad information

Grundläggande information

Försiktighet

- Please note that the swaged flange options, NFC, RFC, and LFC, are not reflected in the CAD data.

Skiss och specifikationer

Back to the Category Toothed Pulleys/Timing Pulleys/Idler Pulleys

Technical Drawing - Toothed Pulleys/Timing Pulleys/Idler Pulleys

Specification Tables - Toothed Pulleys/Timing Pulleys/Idler Pulleys

| Part number | Pulley Shape | Shaft bore dia. dH7 range 1 mm increments | P.D | O.D | F | E | |||||||||||||

| Type | Number of Teeth | Type Nominal Width | HTTA·HTTK | HTTAS | |||||||||||||||

Shape E | Shape F | Shape E | Shape F | ||||||||||||||||

T5100 | T5150 | T5200·T5250 | T5150 | T5200 | T5250 | T5100 | T5150 | T5200·T5250 | T5150 | T5200 | T5250 | ||||||||

| HTTA HTTK HTTAS | 24 | T5100 T5150 T5200 T5250 | E F | 8 | 8 | 8 | 38.2 | 37.4 | 45 | 30 | |||||||||

25 | 39.79 | 39 | |||||||||||||||||

26 | 8·10 | 8·10 | 8·10 | 41.38 | 40.6 | 48 | 35 | ||||||||||||

27 | 42.97 | 42.17 | |||||||||||||||||

28 | 44.56 | 43.75 | |||||||||||||||||

29 | 46.15 | 45.35 | |||||||||||||||||

30 | 10 | 10 | 10 | 47.75 | 46.95 | 52 | 36 | ||||||||||||

31 | 49.34 | 48.53 | 55 | 40 | |||||||||||||||

32 | 10·12· 14 | 10 | 10·12· 14 | 10·12· 14 | 10 | 10·12· 14 | 50.93 | 50.1 | |||||||||||

33 | 52.52 | 51.67 | 61 | 45 | |||||||||||||||

34 | 10·12· 14 | 10·12· 14 to 16 | 10 | 10·12· 14 to 16 | 10·12· 14 | 10·12· 14·15 | 10·12· 14·15 | 54.11 | 53.25 | ||||||||||

35 | 55.7 | 54.85 | |||||||||||||||||

36 | 57.3 | 56.45 | |||||||||||||||||

37 | 58.89 | 58.05 | 67 | 50 | |||||||||||||||

38 | 60.48 | 59.65 | |||||||||||||||||

39 | 62.07 | 61.25 | |||||||||||||||||

40 | 10·12· 14 | 10·12· 14 to 19 | 10 | 10·12· 14 to 19 | 63.66 | 62.85 | |||||||||||||

41 | — | — | 65.25 | 64.43 | 74 | 58 | |||||||||||||

42 | 66.84 | 66.02 | |||||||||||||||||

43 | 68.44 | 67.62 | |||||||||||||||||

44 | 12·14 | 12·14 or more 20·22 | — | 12·14 or more 19 | 12·14 to 20·22 | 12·14 | 12·14· 15·20 | 12·14· 15·20 | — | 12· 14·15 | 12· 14· 15· 20 | 70.03 | 69.2 | ||||||

45 | 71.62 | 70.79 | 80 | 60 | |||||||||||||||

46 | 73.21 | 72.37 | |||||||||||||||||

47 | 74.8 | 73.96 | 83 | 63 | |||||||||||||||

48 | 12·14 | 12·14 or more 20·22 | 12·14 or more 20·22·24 | — | 12·14 or more 19 | 12·14 or more 20·22·24 | 76.39 | 75.55 | |||||||||||

49 | 77.99 | 77.15 | 87 | 67 | |||||||||||||||

50 | 12·14 | 12·14 or more 20·22 | 12·14 or more 20·22· 24·25·28 | — | 12·14 or more 19 | 12·14 or more 20·22·24·25·28 | 12·14· 15·20·25 | — | 12· 14· 15· 20· 25 | 79.58 | 78.75 | ||||||||

51 | 81.17 | 80.34 | |||||||||||||||||

52 | 82.76 | 81.93 | |||||||||||||||||

53 | 84.35 | 83.52 | 95 | 75 | |||||||||||||||

54 | 85.94 | 85.11 | |||||||||||||||||

55 | 87.54 | 86.71 | |||||||||||||||||

56 | 89.13 | 88.3 | |||||||||||||||||

57 | 90.72 | 89.89 | 99 | 80 | |||||||||||||||

58 | 92.31 | 91.48 | |||||||||||||||||

59 | 93.9 | 93.07 | |||||||||||||||||

60 | 12·14 | 12·14 or more 20·22 | 12·14 to 20· 22·24·25·28·30·32 | — | 12·14 or more 19 | 12·14 or more 20·22·24·25·28·30 | 12·14·15· 20·25·30 | — | 12·14·15· 20·25·30 | 95.49 | 94.65 | ||||||||

Alterations - Toothed Pulleys/Timing Pulleys/Idler Pulleys

| Part number | — | Pulley Shape | — | Shaft Bore Dia. | — | (BMC, etc.) |

| HTTA40T5250 | — | E | — | 18 | — | BMC |

| Alterations | Surface Treatment | Flange Cut | No Flange | Single Flange | |

| Code | BMC·BMR | FC | NFC | LFC·RFC | |

| Spec. | Applies electroless nickel plating on a MechaLock. (Antirusting treatment is applied to screws.) [ ! ] Electroless nickel plating decreases bushing's allowable torque by 20 to 30%. BMC: Not RoHS Compliant (Screw: SCM435 Dacrotized Treatment) BMR: RoHS Compliant (Screw: SCM435 GeoMet Coating) | Lowers the flange by cutting. FC: 0.5 mm Increments [ ! ] No surface treatment is applied on flange circumference. | The product is shipped without swaging the flange. (Flange Included) | The product is shipped by swaging the flanges either on the bushing side (LFC) or the opposite side (RFC). (Flange 1 pc. Included) | |

| [ ! ]FC ≥ (O. D.) +1 [ ! ]FC ≤ F-2 Ordering Code FC43 |  |  | ||

Here to the Option Overview PDF