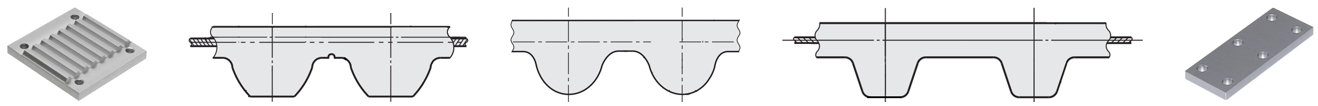

Timing belt guide bar / T#, AT# / PUR / steel

Artikelnummer:

kandidater hittades.Skiss och specifikationstabell

BTG (No Hole)BTGZ (1 Row of Counterbored Holes)

BTG (No Hole)BTGZ (1 Row of Counterbored Holes)| Counterbored Hole | ||||||||||||||||

[ ! ] A ≥ d1 + 6 [ ! ] A ≥ d1 + 6[ ! ] A ≥ d + 6

|

■ Accuracy Standards

| Dimension | Tolerance |

| A·B·C·D·E | ±0.2 |

| L | ±1.0 |

[!] Thermal Expansion Coefficient: 1.7 × 10-4 /°C

[!] Machining Conditions: 3 mm thickness from a hole to the end face is required

[M] Material

UHMWPE

Specification Table

| Part Number | — | L | — | P | — | H | — | K Hole Machining Nominal Dia. | ||

| Type | Nominal | |||||||||

| BTG BTGZ | 150 200 A | — — | 300 1200 | — | P160 | — | H8 | — | K5 | |

| Part Number | L 10 mm Increments | P (Hole Pitch) 5 mm Increments | H Number of Holes | K Hole Machining Nominal Dia. Selection | Applicable Belt Type | A | B | C | D | E | |

| Type | Nominal | ||||||||||

| BTG (No Hole) BTGZ (1 Row of Counterbored Holes) | 100 | 200 to 1800 | — | — | — | T5100·AT5100 | 12 | 8.6 | 20 | 10 | 1.4 |

| 150 | 50 to 500 | 2 to 10 | 4·5·6 | T5150·AT5150 | 17 | 23 | |||||

| 150 A | T10150·AT10150 | 9 | 12 | 3 | |||||||

| 200 | T5200 | 22 | 8.6 | 30 | 10 | 1.4 | |||||

| 200 A | T10200·AT10200 | 9 | 12 | 3 | |||||||

| 250 | T10250·AT10250 | 27 | 35 | ||||||||

| 250B | T5250 | 8.6 | 10 | 1.4 | |||||||

| 300 | T10300 | 32 | 9 | 42 | 12 | 3 | |||||

| 400 | T10400 | 43 | 53 | ||||||||

| 500 | T10500 | 53 | 63 | ||||||||

[NG]Belt Nominal Width 100 is not available for BTGZ.

Artikelnummerlista

| Artikelnummer |

|---|

Enhetspris (exklusive MOMS)(Enhetspris inklusive MOMS) | Standardavsändningsdatum |

|---|

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

- ( - ) | 24 arbetsdagar |

Detaljerad information

Skiss och specifikationer

App. Example

General Information - Timing Belts

Timing Belt Selection Details

- Material: chloroprene rubber (neoprene), polyurethane (PU)

- Tension cord: glass fibre, aramid fibre, steel

- Width (mm): 1 to 101.6

- Width (in.): 0.19 to 4

- Profile (metric): T5, T10, AT5, AT10, S2M, S3M, S5M, S8M, S14M, MTS8M, EV5GT, EV8YU, 2GT, 3GT, MA3, MA5, MA8, P2M, P3M, P5M, P8M, UP5M, UP8M

- Profile (in.): MXL, XL, L, H

Description/Basics

Timing belts for mechanical engineering are intended for force and power transmission. Depending on the interlocking of the profile, they can alternatively be used for the material flow (transportation) or for positioning.

Timing belts are more maintenance-friendly, efficient and durable compared to roller chains.

Maintenance-friendly: timing belts do not require lubrication, are easy to replace and are very durable, as they do not sag. These properties significantly reduce maintenance costs.

Efficient: drive belts are largely made of natural rubber or polyurethane. As a result, timing belts withstand high speeds. A further advantage of these materials is the weight reduction compared to conventional metal drives. Timing belts are also known for low-noise running and contribute to the general smooth running of an application.

Durability: due to the inserted tension cord made of glass fibre or aramid fibre (Kevlar), timing belts can withstand high tensile stresses and do not tend to sag. An additional layer of nylon fabric on the interlocked side reduces wear due to abrasion and increases the service life.

Timing belts can be used in many ways. The belt profile that suits your application depends on the task of the timing belt. MISUMI offers a suitable belt profile for almost every type of application.

Drive: timing belts are used even at high torque. Drive belts with a rounded trapezoidal profile (e.g., S8M) are often used to drive mechanical components. These are particularly well suited for slip-free transmission of high forces, which can occur in drives of various applications or machines.

Positioning: a semi-circular profile (e.g., GT) is often used for positioning via timing belts. Round profile timing belts are often used in 3D printers and precise scanners. The round shape also offers the advantage that there is little play (reverse play) when the direction changes.

Material flow: timing belts can also be used to transport loads in conveyor systems. A straight trapezoidal profile is often used for this purpose (e.g., AT ). This profile provides a large profile area for load intake and transmission. The MISUMI range also includes conveyor timing belts with nylon fabric on the bearing surface.

An overview of the profile forms by application type can be found in the PDF Overview.

The amount of transmission power depends on many factors. The exact maximum load must be considered and calculated individually according to the application. The calculation for timing belts can be found in the selection of Timing Belts as PDF.

In order not to fall below the minimum number of teeth, the minimum size of the timing pulleys should be considered individually.

In general, a timing belt should be provided with the appropriate pretension to maximize the service life of the timing belt. If the pretension is too low, a jump (slip) can cause wear of the timing belt.

Application Examples - Timing Belts

Application example: workpiece carrier

(1) Stopper bolt with rubber, (2) belt conveyor, (3) workpiece carrier

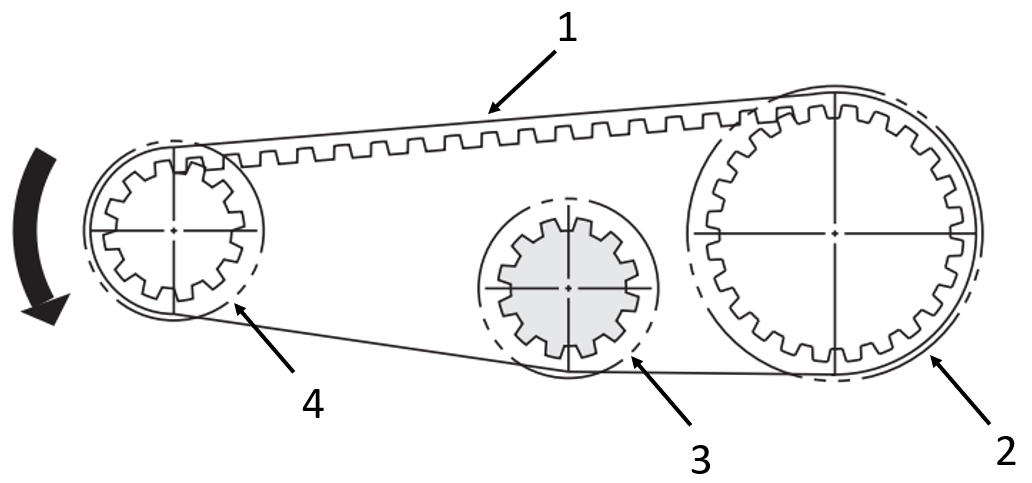

Application example: of toothed belt drives

(1) Toothed belt, (2) driven Timing pulleys with crimp disc, (3) idler pulley with crimp disc, (4) driving Timing pulleys with crimp disc

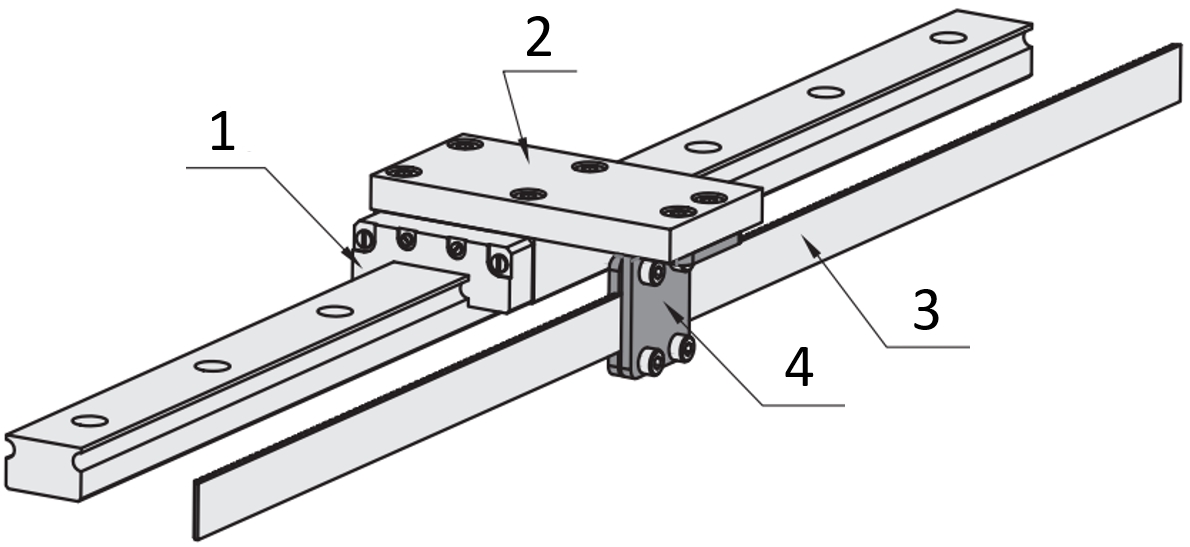

Application example: Timing belt

(1) Linear guide, (2) mounting plate, (3) Timing belt, (4) Screw-on terminal

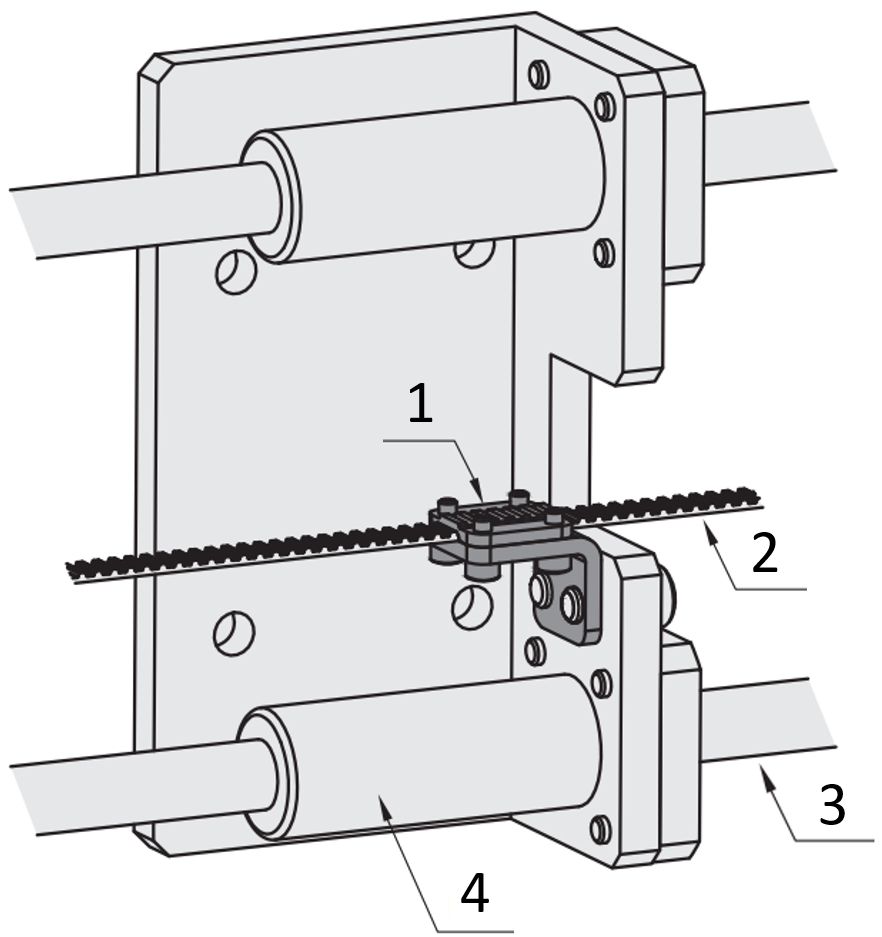

Application example: Timing belt

(1) Bolt-on terminal, (2) Timing belt, (3) Linear shaft, (4) Linear bushings

Industrial Applications