Filtreringsvillkor

- Shank Diameter d(mm)

- 3

- 4

- 6

- 8

- 10

- 12

- 16

- Overall Length L(mm)

- 40

- 50

- 60

- 80

- 90

- 100

- 120

- Processing Applications

- #2[0.4-16/0.01][0.4-16/0.005]

- #3[0.1-12/0.01][0.4-12/0.005]

- #4[0.1-5.9/0.01][0.5-48/0.5]

- #5[0.5-36/0.5]

- F

- T

- Uppskattade leveransdagar

- Alla

- Inom 7 arbetsdagar

- Inom 8 arbetsdagar

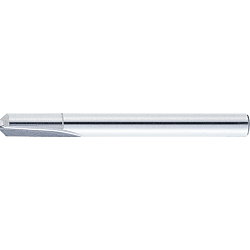

Carbide Straight Edge Corner C End Mill, 2-flute

Artikelnummer:

kandidater hittades.Skiss

Artikelnummerlista

Antal artiklar

| Artikelnummer |

|---|

Enhetspris (exklusive MOMS)(Enhetspris inklusive MOMS) | Standardavsändningsdatum |

|---|

- ( - ) | 8 arbetsdagar |

- ( - ) | 8 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 8 arbetsdagar |

- ( - ) | 8 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 8 arbetsdagar |

- ( - ) | 8 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 8 arbetsdagar |

- ( - ) | 8 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

- ( - ) | 7 arbetsdagar |

Detaljerad information

Grundläggande information

[Features]

-Product range with standard corner bevels and circular grinding

-Specifying changes makes it possible to select a coating suitable for the work material

-Can be reground. Please refer to the "Regrinding Service" page for information on use, range of services, prices, etc.

Specifikationer och pris

Specification Table

| Model Number | Blade Diameter D 0.005 mm Unit Specification | Corner C 0.01mm Unit Specification | Blade Length ℓ 0.5 mm Unit Specification | Blade Shape (Selection) | Overall Length L | ||

| Shank diameter d | |||||||

| BSCC | LS−BSCC | ||||||

| BSCC LS−BSCC (Long Shank) | 3 | 0.400 to 0.500 | 0.10 ≤ C ≤ (D-0.2)/2 | 0.5 to 1.0 | T (Indented Center) F (Flat) | 40 | 60 |

| 0.505 to 1.500 | 0.5 to 5.0 | 40 | 60 | ||||

| 1.505 to 2.000 | 0.5 to 10.0 | 40 | 60 | ||||

| 2.005 to 3.000 | 0.5 to 15.0 | 40 | 60 | ||||

| 4 | 2.005 to 4.000 | 0.5 to 20.0 | 50 | 80 | |||

| 6 | 3.005 to 6.000 | 3.0 to 24.0 | 60 | 90 | |||

| 8 | 4.005 to 8.000 | 4.0 to 28.0 | 60 | 90 | |||

| 10 | 6.005 to 10.000 | 5.0 to 35.0 | 80 | 120 | |||

| 12 | 8.005 to 12.000 | 6.0 to 36.0 | 80 | 120 | |||

| 16 | 10.005 to 16.000 | 8.0 to 48.0 | 100 | − | |||

| Model Number | Blade Diameter D 0.01mm Unit Specification | Corner C 0.01mm Unit Specification | Blade Length ℓ 0.5 mm Unit Specification | Blade Shape (Selection) | Overall Length L | ||

| Shank diameter d | |||||||

| SCEM | LS−SCEM | ||||||

| SCEM LS−SCEM (Long Shank) | 3 | 0.40 to 0.50 | 0.10 ≤ C ≤ (D-0.2)/2 | 0.5 to 1.0 | T (Indented Center) F (Flat) | 40 | 60 |

| 0.51 to 1.50 | 0.5 to 5.0 | 40 | 60 | ||||

| 1.51 to 2.00 | 0.5 to 10.0 | 40 | 60 | ||||

| 2.01 to 3.00 | 0.5 to 15.0 | 40 | 60 | ||||

| 4 | 2.01 to 4.00 | 0.5 to 20.0 | 50 | 80 | |||

| 6 | 3.01 to 6.00 | 3.0 to 24.0 | 60 | 90 | |||

| 8 | 4.01 to 8.00 | 4.0 to 28.0 | 60 | 90 | |||

| 10 | 6.01 to 10.00 | 5.0 to 35.0 | 80 | 120 | |||

| 12 | 8.01 to 12.00 | 6.0 to 36.0 | 80 | 120 | |||

| 16 | 10.01 to 16.00 | 8.0 to 48.0 | 100 | − | |||

● BSCC/LS−BSCC

Click here for the cutting conditions (Cutting by end mill for carbide straight edge boss machining)

● SCEM/LS−SCEM

Click here for cutting conditions (groove cutting with customized straight blade end mill)