Drill bushes / thin-walled / bore +0.01 / configurable / steel, stainless steel / 50HRC-60HRC

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

- Technical Information

Back to the Category Bushings for Fixtures

Technical Drawing - Flanged Drill Bushes

Open the technical drawing in the new window

Available dimensions and tolerances can be found under the tab More information.

Overview of the various designs as PDF

Basic Properties (e.g., material, hardness, coating, tolerance) - Flanged Drill Bushes

| Material | Surface Treatment | Hardness | Type | |

| p6 | m6 | |||

| EN 1.2510 Equiv. | - | 56~60HRC | JBAUFP | JBAUF |

| EN 1.2510 Equiv. | Black Oxide | 56~60HRC | JBAUFBP | JBAUFB |

| EN 1.2510 Equiv. | Electroless Nickel Plating | 56~60HRC | JBAUFMP | JBAUFM |

| EN 1.4037 Equiv. | - | 50~55HRC | JBAUFCP | JBAUFC |

Further specifications can be found under the tab More information.

Composition of a Product Code - Flanged Drill Bushes

| Part Number | - | P | - | L |

| JBAF10 JBAUFC10 | - - | P4.00 P8.00 | - - | L8.5 L15.0 |

Alterations - Flanged Drill Bushes

General Information - Flanged Drill Bushes

Selection between drill bushings / positioning bushings / centering bushings

- Material: steel, stainless steel, brass, ceramics

- Coatings: untreated, nickel-plated, burnished

- Hardness: 50HRC to 62HRC

- Fastening: with notch, mounting bracket, with dowel pin, pressed-in

- Inside diameter shape: round, oval

- ISO tolerances: g6, h6, m6, n6, p6, 0/-0.2, 0/-0.01

- Inside diameter: 2 mm to 35 mm

- Outside diameter: 5 mm to 48 mm

- Length: 3 mm to 60 mm

Here to the drill bushings Overview as PDF

Description / Basics

A drill bushing is intended for precise centering, positioning and guidance of drills. They can be used in drilling rigs or for multi-spindle drilling heads as well as a drilling jig. Therefore, it is possible to create an accurate and recurring bore at the same position in one component. In addition, through the guide the drill bushing protects the drill from breakage. The most common bushings are the collar drill bushing according to DIN 172 and the cylindrical drill bushing according to DIN 179.

Drill bushings and collar drill bushings are available in a variety of fastening types. They can be pressed in or secured with a semi-circular notch in the collar of the plug-in fulcrum pins. Since it is not pressed, this has the advantage of quick interchangeability. MISUMI also offers the special form of a flanged bushing with mounting flange.

Collar bushings with oval bores are also available at MISUMI. These are provided with a semi-circular notch in the collar, which, in combination with a dowel pin, serves to align the collar drill bushing.

Drill bushings are often used as positioning bushings or centering bushings.

Due to the rounded insertion of the drill bushing, it can serve as a joining opening for centering pins or height adjusting pins.

Application Examples - Flanged Drill Bushes

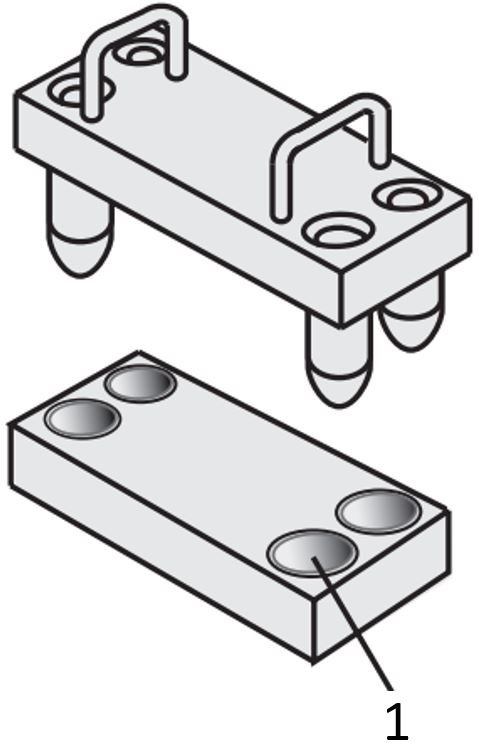

Example for using a centering bolt/centering bushing with collar

(1) Locating pin, (2) Bushings for fixtures

Example for using a centering bolt/centering bushing

(1) Locating pin , (2) Bushings for fixtures, (3) Mounting plate

Industrial Applications

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number | Minimum order quantity | Volume Discount | RoHS | Inner Diameter (mm) | Outer Diameter (mm) | Outer Diameter Tolerance | Material | Surface Treatment | O.D. D (mm) | Length L (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 25 Days | 10 | 3.51 ~ 5 | 7 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 7 | 5 ~ 8 | ||

| 1 | 25 Days | 10 | 4.51 ~ 6 | 8 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 8 | 5 ~ 13 | ||

| 1 | 25 Days | 10 | 4.51 ~ 6.5 | 9 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 9 | 5 ~ 13 | ||

| 1 | 25 Days | 10 | 6.51 ~ 8 | 10 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 10 | 5 ~ 20 | ||

| 1 | 25 Days | 10 | 8 ~ 9 | 11 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 11 | 5 ~ 20 | ||

| 1 | 25 Days | 10 | 8.51 ~ 9 | 12 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 12 | 5 ~ 20 | ||

| 1 | 25 Days | 10 | 8.51 ~ 10 | 13 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 13 | 5 ~ 20 | ||

| 1 | 25 Days | 10 | 9 ~ 11 | 14 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 14 | 5 ~ 20 | ||

| 1 | 25 Days | 10 | 10.51 ~ 12 | 15 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 15 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 10.51 ~ 13 | 17 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 17 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 12.51 ~ 14 | 18 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 18 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 13.51 ~ 15 | 20 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 20 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 13.51 ~ 17 | 22 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 22 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 15.51 ~ 19 | 25 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 25 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 16.51 ~ 20 | 26 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 26 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 20.51 ~ 24 | 30 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 30 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 25.01 ~ 29 | 35 | m6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 35 | 5 ~ 60 | ||

| 1 | 25 Days | 10 | 3.51 ~ 5 | 7 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 7 | 5 ~ 8 | ||

| 1 | 25 Days | 10 | 4.51 ~ 6 | 8 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 8 | 5 ~ 13 | ||

| 1 | 25 Days | 10 | 4.51 ~ 6.5 | 9 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 9 | 5 ~ 13 | ||

| 1 | 25 Days | 10 | 6.51 ~ 8 | 10 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 10 | 5 ~ 20 | ||

| 1 | 25 Days | 10 | 8 ~ 9 | 11 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 11 | 5 ~ 20 | ||

| 1 | 25 Days | 10 | 8.51 ~ 9 | 12 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 12 | 5 ~ 20 | ||

| 1 | 25 Days | 10 | 8.51 ~ 10 | 13 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 13 | 5 ~ 20 | ||

| 1 | 25 Days | 10 | 9 ~ 11 | 14 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 14 | 5 ~ 20 | ||

| 1 | 25 Days | 10 | 10.51 ~ 12 | 15 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 15 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 10.51 ~ 13 | 17 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 17 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 12.51 ~ 14 | 18 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 18 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 13.51 ~ 15 | 20 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 20 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 13.51 ~ 17 | 22 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 22 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 15.51 ~ 19 | 25 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 25 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 16.51 ~ 20 | 26 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 26 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 20.51 ~ 24 | 30 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 30 | 5 ~ 40 | ||

| 1 | 25 Days | 10 | 25.01 ~ 29 | 35 | p6 | [Steel] EN 1.2510 Equiv. | Black Oxide | 35 | 5 ~ 60 |

Loading...

Back to the Category Bushings for Fixtures

Technical Drawing - Flanged Drill Bushes

Open the technical drawing in the new window

Available dimensions and tolerances can be found under the tab More information.

Overview of the various designs as PDF

Specification Tables - Flanged Drill Bushes

| Part Number | P 0.01mm Increment | L 0.1mm Increment | Thickness (N) | R | Unit Price | ||||||

| Type | D | D Tolerance | JBAUF JBAUFP | JBAUFB JBAUFBP | JBAUFM JBAUFMP | JBAUFC JBAUFCP | |||||

| p6 | m6 | ||||||||||

| (p6) JBAUFP JBAUFBP JBAUFMP JBAUFCP (m6) JBAUF JBAUFB JBAUFM JBAUFC | 7 | +0.024 +0.015 | +0.015 +0.006 | 3.51~5.00 | 5.0~8.0 | 1.00~1.74 | 0.5 | ||||

| 8 | 4.51~6.00 | 5.0~13.0 | |||||||||

| 9 | 4.51~6.50 | 1.25~2.24 | |||||||||

| 10 | 6.51~8.00 | 5.0~20.0 | 1.00~1.74 | ||||||||

| 11 | +0.029 +0.018 | +0.018 +0.007 | 8.00~9.00 | 1.00~1.50 | |||||||

| 12 | 8.51~9.00 | 1.50~1.74 | |||||||||

| 13 | 8.51~10.00 | 1.50~2.24 | |||||||||

| 14 | 9.00~11.00 | 1.50~2.50 | |||||||||

| 15 | 10.51~12.00 | 5.0~40.0 | 1.50~2.24 | ||||||||

| 17 | 10.51~13.00 | 2.00~3.24 | 1.0 | ||||||||

| 18 | 12.51~14.00 | 2.00~2.74 | |||||||||

| 20 | +0.035 +0.022 | +0.021 +0.008 | 13.51~15.00 | 2.50~3.24 | |||||||

| 22 | 13.51~17.00 | 2.50~4.24 | |||||||||

| 25 | 15.51~19.00 | 3.00~4.74 | |||||||||

| 26 | 16.51~20.00 | 3.00~4.74 | |||||||||

| 30 | 20.51~24.00 | 3.00~4.74 | 1.5 | ||||||||

| 35 | +0.042 +0.026 | +0.025 +0.009 | 25.01~29.00 | 5.0~60.0 | 3.00~4.99 | ||||||

| L≤Px2.5 when P≤3.59 L≤Px3.0 when P≥3.60 | |||||||||||

Alterations - Flanged Drill Bushes

Basic information

| Basic Shape | Straight | Inner Diameter Shape | Circular Shape | Fixing Support | Not Provided |

|---|

Configure

Basic Attributes

-

Inner Diameter(mm)

-

Outer Diameter(mm)

-

Outer Diameter Tolerance

-

Material

- Steel

- Stainless Steel

- Steel

-

O.D. D(mm)

-

Length L(mm)

-

Type

- JBAUF

- JBAUFB

- JBAUFBP

- JBAUFC

- JBAUFCP

- JBAUFM

- JBAUFMP

- JBAUFP

-

Surface Treatment

- Not Provided

- Electroless Nickel Plating

- Black Oxide

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 25 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

Can you press in a drill bushing?

-

Answer:

A drill bushing or collar bushing can be pressed in. However, it should be noted that the inner diameter of the drill bushing may become smaller if the tolerance is too tight. For more information, see the Technical Data Sheet available as a PDF. It is recommended to select a non-tight press fit and to additionally secure the bushing with screw locking agents such as Loctite.

-

Question:

Are there gentle positioning bushings for centring pins?

-

Answer:

MISUMI offers gentle drill bushings and collar bushings made of brass. These consist of a softer material than drill bushings made of steel. In the case of frequent joining processes, increased wear is thus directed onto the drill bushing and therefore the wear of the centring pin is reduced. However, wear should often be checked for brass bore bushings and attention should be paid to the resulting play.

-

Question:

What is a drill bushing?

-

Answer:

A drill bushing is primarily used to guide and centre drill bits. These are often used in drilling templates and drilling gauges and help to precisely enable a repetitive position of the drilling. In addition, a drill bushing of the guide and support of a drill helps and can protect it from breakage. The drill bushings are also often used as a positioning bushing for centring pins. This means that positioning bushings can also be used in a workpiece carrier.

-

Question:

Can a drill bushing corrode?

-

Answer:

A drill bushing made of steel can oxidize (rust). If necessary, a stainless steel drill bushing can also be used. MISUMI also offers the drill bushing and positioning bushing made of steel with various surface treatments. These are available in either burnished or nickel-plated and protect against corrosion.

-

Question:

How can you prevent tilting in a centring bushing?

-

Answer:

In order to prevent tilting, a positioning bushing with oval bore can be used, as this allows length compensation in one direction. A possible cause of tilting can be a misalignment caused by temperature-related expansion or stress. Alternatively, a sword pin with a conventional drill bushing can be used to prevent tilting.

-

Question:

Which fit for drill bushings?

-

Answer:

Which bore tolerance fits depends on the application and the selected external tolerance of the drill bushing. Often, an H7 tolerance for the bore is used for pressing in. For more information about fitting, see Dimensional Tolerances and Fits available as a PDF.

-

Question:

Does a drill bushing need to be pressed in?

-

Answer:

It is not mandatory to press in a drill bushing or positioning bushing. A socket drill bushing is assembled and disassembled with a shoulder screw. Another variant is the drill bushing with mounting flange (large collar with through-holes), which is screwed to the flange. MISUMI also provides cylindrical drill bushings and collar bushings with a lateral groove that can be fixed with an adjusting screw or set screw.

-

Question:

Do you have stainless steel drill bushings?

-

Answer:

The cylindrical bore bushings and collared bore bushings are available in steel, stainless steel and brass.

These can be selected to the usual dimensions such as DIN 172 and DIN 179. However, MISUMI also offers configurable drill bits the length of which can be individually adjusted to your needs in 0.1 mm increments and the diameter in 0.01 mm increments.

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry

![[Precision] X-Axis / Cross Roller](http://content.misumi-ec.com/image/upload/f_auto,t_product_recommend_a/v1/p/jp/product/series/110300196460/110300196460_001.jpg)