Angle brackets / through hole, parallel pin bore / aluminium, steel / welded-on rib

- Volume Discount

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

| Type | [M] Material | [S] Surface Treatment | |

| No Hole | Hole Positions Configurable | ||

| IKYSB | IKYS | EN 1.0038 Equiv. | Black Oxide |

| IKYSAB | IKYSA | EN AW−5052 Equiv. | — |

Specification Table

| Part Number | — | A |

| IKYSB100 | — | 100 |

| Part Number | — | A | — | B | — | X | — | F | — | Y | — | G |

| IKYS120 | — | A100 | — | B75 | — | X40 | — | F30 | — | Y40 | — | G50 |

| Part Number | A | W | T | T1 | E | |

| Type | H | |||||

| IKYSB IKYSAB | 100 | 50 | 100 | 10 (10) | 9 (10) | 65 |

| 100 | ||||||

| 120 | 100 | 80 | ||||

| 150 | 100 | 100 | ||||

| 200 | 60 | 135 | ||||

| 100 | ||||||

| 250 | 60 | 14 (13) | 12 (12) | 165 | ||

| 100 | ||||||

| 300 | 100 | 200 | ||||

| 350 | 120 | 235 | ||||

| 400 | 150 | 20 (23) | 16 (15) | 265 | ||

| 500 | 150 | 335 | ||||

■Hole Position Configurable

| Part Number | A | 1 mm Increments | Fixed Dimension | ||||||||||||

| B | X | F | Y | G | W | T | T1 | E | a | h | D | d | |||

| Type | H | ||||||||||||||

| IKYS IKYSA | 100 | 50 | 50 to 75 | 30 to 35 | — | 35 to 55 | 30 to 50 | 100 | 10 (10) | 9 (10) | 65 | X+ (F/2) | Y+ (G/2) | 10 | 11 |

| 100 | 30 to 55 | 30 to 55 | |||||||||||||

| 120 | 100 | 35 to 75 | 30 to 70 | 80 | |||||||||||

| 150 | 100 | 35 to 105 | 30 to 100 | 100 | |||||||||||

| 200 | 60 | 35 to 45 | — | 35 to 155 | 30 to 150 | 135 | |||||||||

| 100 | 35 to 55 | 30 to 50 | |||||||||||||

| 250 | 60 | 35 to 45 | — | 50 to 205 | 30 to 185 | 14 (13) | 12 (12) | 165 | |||||||

| 100 | 35 to 55 | 30 to 50 | |||||||||||||

| 300 | 100 | 50 to 255 | 30 to 235 | 200 | |||||||||||

| 350 | 120 | 40 to 75 | 30 to 65 | 50 to 305 | 30 to 285 | 235 | |||||||||

| 400 | 150 | 40 to 105 | 30 to 95 | 50 to 355 | 30 to 335 | 20 (23) | 16 (15) | 265 | |||||||

| 500 | 150 | 50 to 455 | 30 to 435 | 335 | |||||||||||

Alterations

| Part Number | — | A | — | B | — | X | — | F | — | Y | — | G | — | (NKC·LN・HN・MC) |

| IKYS120 | — | A100 | — | B75 | — | X40 | — | F30 | — | Y40 | — | G50 | — | NKC |

| Alterations | Omit Dowel Holes | Slotted Hole | Tapped Hole | ||||||||||||||||||||||||||||||||||||||||||||||||

|  |  |  | ||||||||||||||||||||||||||||||||||||||||||||||||

| Code | NKC | LN | HN | MC | |||||||||||||||||||||||||||||||||||||||||||||||

| Spec. | Omits all dowel holes. Ordering Code NKC | Changes the d holes on A surface to slotted holes. Ordering Code LN [ ! ] When A = 50 or 60, two slotted holes are machined. [ ! ] When A = 50, the slotted hole length is 10 mm. | Changes the d holes on H surface to slotted holes. Ordering Code HN [ ! ] When H = 100, 120 or 150, the slotted hole distance is 20 mm. | Changes the holes 4-d (ø11 Through Holes) on side H to tapped holes M10. Ordering Code MC | |||||||||||||||||||||||||||||||||||||||||||||||

| * There is no dowel hole on the slotted hole side. |

| * There is no dowel hole on the slotted hole side. |

| ||||||||||||||||||||||||||||||||||||||||||||||||

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Material | Hole Machining | Surface Treatment | Height H (mm) | Dimension A (mm) | B (mm) | F (mm) | G (mm) | X (mm) | Y (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 100 | 50 | 50 ~ 75 | - | 30 ~ 50 | 30 ~ 35 | 35 ~ 55 | ||

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 100 | 100 | 50 ~ 75 | 30 ~ 55 | 30 ~ 50 | 30 ~ 55 | 35 ~ 55 | ||

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 120 | 100 | 50 ~ 75 | 30 ~ 55 | 30 ~ 70 | 30 ~ 55 | 35 ~ 75 | ||

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 150 | 100 | 50 ~ 75 | 30 ~ 55 | 30 ~ 100 | 30 ~ 55 | 35 ~ 105 | ||

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 200 | 60 | 50 ~ 75 | - | 30 ~ 150 | 35 ~ 45 | 35 ~ 155 | ||

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 200 | 100 | 50 ~ 75 | 30 ~ 50 | 30 ~ 150 | 35 ~ 55 | 35 ~ 155 | ||

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 250 | 60 | 50 ~ 75 | - | 30 ~ 185 | 35 ~ 45 | 50 ~ 205 | ||

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 250 | 100 | 50 ~ 75 | 30 ~ 50 | 30 ~ 185 | 35 ~ 55 | 50 ~ 205 | ||

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 300 | 100 | 50 ~ 75 | 30 ~ 50 | 30 ~ 235 | 35 ~ 55 | 50 ~ 255 | ||

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 350 | 120 | 50 ~ 75 | 30 ~ 65 | 30 ~ 285 | 40 ~ 75 | 50 ~ 305 | ||

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 400 | 150 | 50 ~ 75 | 30 ~ 95 | 30 ~ 335 | 40 ~ 105 | 50 ~ 355 | ||

- | 1 | 13 Days | 10 | Steel | Through Holes and Dowel Holes | Black Oxide | 500 | 150 | 50 ~ 75 | 30 ~ 95 | 30 ~ 435 | 40 ~ 105 | 50 ~ 455 | ||

69.70 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 100 | 50 | - | - | - | - | - | |

72.42 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 100 | 100 | - | - | - | - | - | |

74.37 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 120 | 100 | - | - | - | - | - | |

81.15 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 150 | 100 | - | - | - | - | - | |

100.13 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 200 | 60 | - | - | - | - | - | |

102.67 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 200 | 100 | - | - | - | - | - | |

115.32 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 250 | 60 | - | - | - | - | - | |

116.52 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 250 | 100 | - | - | - | - | - | |

128.42 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 300 | 100 | - | - | - | - | - | |

147.25 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 350 | 120 | - | - | - | - | - | |

181.58 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 400 | 150 | - | - | - | - | - | |

226.14 € | 1 | Available | 13 Days | 10 | Steel | No Hole | Black Oxide | 500 | 150 | - | - | - | - | - |

Loading...

General Information - Angle Brackets

Angle Bracket Selection Details

- Material: aluminum, steel, cast steel, stainless steel

- Coatings: untreated, burnished, primed (grey), nickel-plated

- Design: cast, welded

- Perpendicularity: up to 0.02/100

- Bore holes: without bore hole, through-hole, internal thread, dowel pin bore, oblong hole

- Dowel pin bore: H7

- Length A: 40 to 150 mm

- Length H: 50 to 500 mm

- Width: 30 to 100 mm

Description/Basics

Basically, an angle bracket is used for precise and solid fastening or connecting of different components and as frame constructions in mechanical and plant engineering. In most cases, angle brackets are uneven.

Due to its high perpendicularity, an angle bracket is among the precise mounting angles. Thanks to their stiffening rib, the angle bracket is also more solid and stiffer than conventional mounting angles and offers a precise, robust and secure connection.

MISUMI offers angle brackets with configurable through holes and dowel pin bores. The through hole can be converted to a tapped hole using the [MC] option. In addition, with the help of the option [LN, HN], the through hole of the angle brackets can be changed to an elongated hole. The angle bracket itself or the element to be fastened can thus be adjusted. The optional dowel pin holes in conjunction with dowel pins offer the possibility of aligning and mounting components such as manual stages, cylinders or other devices as accurately as possible on an angle bracket.

Our angle brackets are also available as blanks without mounting holes for individual machining.

Due to the many variations of an angle bracket, it offers design flexibility. This allows adapting it to the machine environment. With MISUMI, you can configure and have your steel brackets customized or stainless steel angles customized.

Angle brackets are often used as cylinder holders for air cylinders, as the exact straightness and exact position of the dowel pin bores allow for exact positioning of the cylinders. An angle console is also suitable for holding and holding positioning stages. Occasionally, the angle bracket is also used in clamping technology to accommodate the push-pull toggle clamps, clamp cylinder or gripper.

MISUMI offers for assembly different threaded rods and nuts, as well as washers.

Steel angle bracket/steel bracket

The benefits an angle bracket made of steel (cast steel) provides are primarily its high strength and the load capacity of the base material. As a result, steel angle brackets can absorb high loads.

Since steel has good quality, it is less expensive to manufacture, easy to rework and welds well. Compared to many other metallic raw materials, steel is quite cost-effective and can therefore be found in many applications.

Thanks to its good thermal conductivity, a steel angle or steel angle bracket can be used in areas with high temperatures. Since steel tends to oxidize, a coating should be provided as much as possible depending on the angle bracket. For this purpose, you can choose between either burnished, nickel-plated or primed.

Stainless steel angle bracket/stainless steel bracket

Angle brackets made of steel or stainless steel are characterized by their high durability. Thanks to their resistance, stainless steel angle brackets are very robust and stable. They are less prone to corrosion because the chrome content forms a passive layer (oxide film). Especially in corrosive environments, it is possible to use an angle bracket made of stainless steel (stainless steel), since the base material is very high-quality. Stainless steel also has high temperature resistance and can be welded. However, at higher temperatures, or even when welding the material, discoloration can occur (tempering colour). The stainless steel angles are also hygienic due to the material and are often used in medical technology.

Aluminum angle bracket/aluminum bracket

An important advantage of aluminum angle brackets is their reduced weight compared to steel or stainless steel angle brackets. This special feature can contribute to weight reduction in many applications. With regard to the low weight, the aluminum angle brackets have by comparison a high strength and can withstand high loads.

In addition, the simple processing and post-processing of the material makes the aluminum angle consoles cost-efficient. Similar to stainless steel, aluminum forms an oxide film and is thus well protected against corrosion. Another advantage of the angle bracket made of aluminum is that the base material has a low thermal expansion. This allows these angle consoles to be used in applications that are subject to frequent temperature changes. Angle consoles made of aluminum also have good electrical conductivity and can thus dissipate electrical voltages such as electrical static charges. This is often necessary in electrical systems or in the electronics industry for the production of electronic components.

Application Examples - Angle Brackets

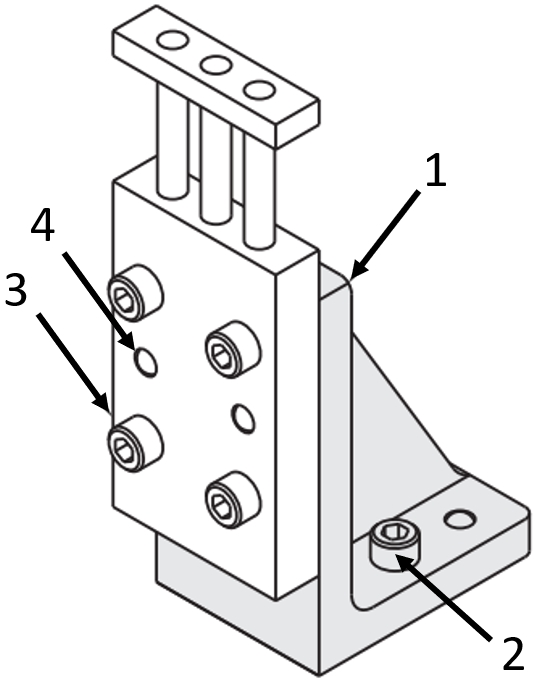

Application example: angle bracket with guide cylinder

(1) Angle bracket, (2) Hexagon socket screw, (3) Air cylinder, (4) Dowel pin

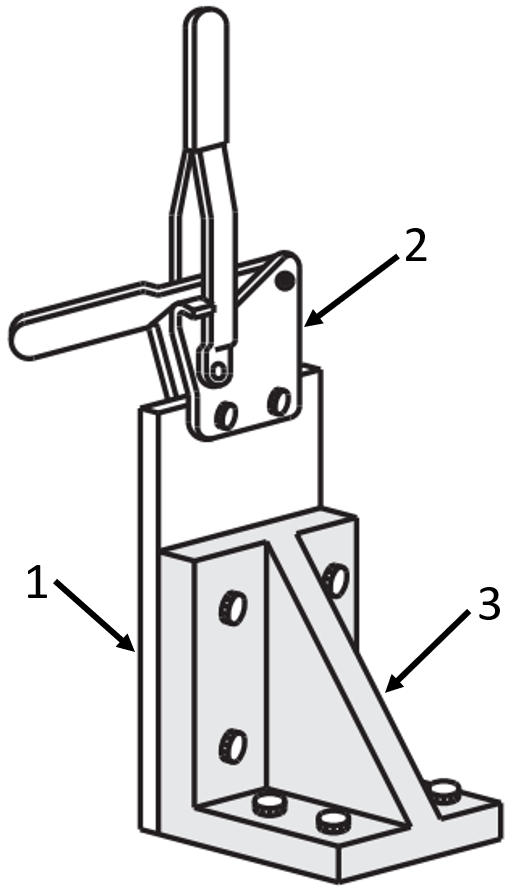

Application example: angle bracket with push-pull toggle clamps

(1) Mounting plate, (2) push-pull toggle clamps, (3) angle bracket

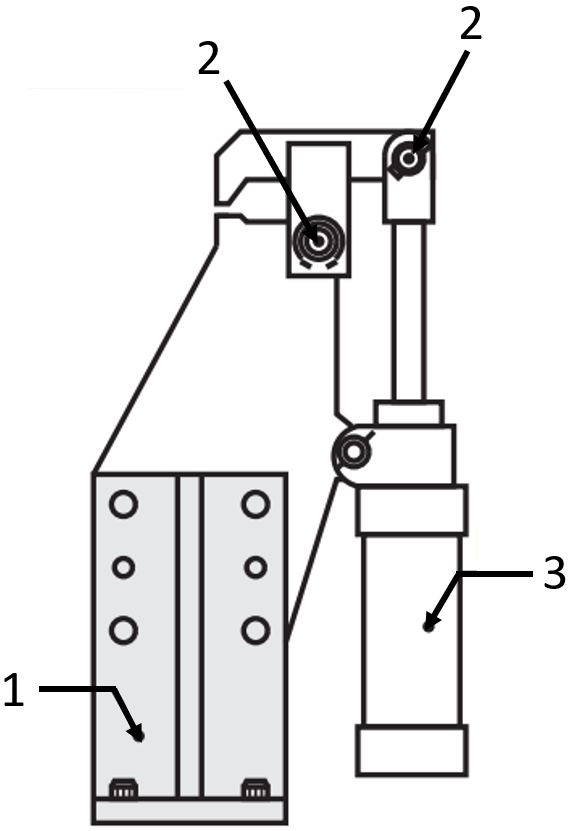

Application example: angle bracket with cylinder

(1) Angle bracket, (2) hinge bolts, (3) cylinder

Industrial Applications

Basic information

| Strength | High Strength (Welding) |

|---|

Configure

Basic Attributes

-

Material

- Steel

- Aluminum

-

Hole Machining

- Through Holes and Dowel Holes

- No Hole

-

Height H(mm)

-

Dimension A(mm)

-

B(mm)

-

F(mm)

-

G(mm)

-

X(mm)

-

Y(mm)

-

Type

- IKYS

- IKYSA

- IKYSAB

- IKYSB

-

Surface Treatment

- Black Oxide

- Not Provided

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 13 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

What do you use the angle brackets for?

-

Answer:

An angle bracket can be used for a wide variety of applications in mechanical engineering. In general, they are used to connect or fix different components and devices. Angle brackets are manufactured very precisely with their perpendicularity compared to conventional mounting angles. Therefore, angle brackets are also frequently used to accommodate pneumatic cylinders, positioning stages, and stages. Another benefit of the angle bracket is its high rigidity due to the additional stiffening rib. This provides the angle bracket with a very good stability. Therefore, it can absorb heavier loads compared to normal angles.

-

Question:

What are the different types of steel on angle brackets?

-

Answer:

MISUMI offers the massive and precise angle bracket in two different types of steel. The MISUMI product range offers the material EN 1.0038 equivalent, which is also known as S235JR. This material is often used for extruded profiles. This shows good ductility, toughness and plasticity. As a further material, the range contains the EN-JL 1040 equivalent. This is grey cast iron with slat graphite, which has very good workability and is often used in machine tools.

-

Question:

What coatings are available for angle brackets made of steel?

-

Answer:

Our angle brackets are available untreated for further processing. To protect against corrosion, the angle bracket can be burnished, primed (grey) and nickel-plated.

-

Question:

What are the advantages of aluminum brackets?

-

Answer:

Aluminum brackets and aluminum angle brackets have a low weight and are therefore suitable for weight reduction. Aluminum, on the other hand, has a high strength in relation to heavier materials. As a result, these are also suitable for high loads. Another advantage is that aluminum does not require further corrosion protection. In addition, aluminum has a low thermal expansion, which gives it dimensional stability in case of temperature fluctuations.

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry

![[Precision] X-Axis / Cross Roller](http://content.misumi-ec.com/image/upload/f_auto,t_product_recommend_a/v1/p/jp/product/series/110300196460/110300196460_001.jpg)