Jig Pins / Standard(h7) / Bullet Nose / Shoulder

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- Catalog

- Technical Information

| Type | Retaining Part Shape | Shape | Material | Hardness |

| HATA | N (Threaded) T (Set Screw) B (Screw Mounted) | Round | EN 1.7220 Equiv. | Treated Hardness 35~40HRC |

| HATD | Diamond | |||

| THATA | Round | EN 1.7242 Equiv. | Carburized Treated Hardness: 55HRC~ (Depth: 0.7 ~ 0.8) / Anti-carburizing on Threads | |

| THATD | Diamond |

| Type | Retaining Part Shape | Shape | Material | Hardness | Surface Treatment |

| D-HATA | N (Threaded) T (Threaded) | Round | EN 1.7220 Equiv. | 55HRC~ (Surface 3000HV) | Dicoat® Treated |

| D-HATD | Diamond |

Specifications

| Part Number | - | P | - | B | - | L | ||||

| Type | Retaining Part Shape | D | ||||||||

| HATA | N | 8 | - | P7.8 | - | B15 | - | L8 | ||

| HNTAX | T | 8 | - | P12.0 | - | B15 | ||||

| Part Number | P 0.1mm Increment | B 1mm Increment | L | ℓ | L1 | ℓ1 | d | Applicable Set Screw | M (Coarse) | H | R | W | ||||||||||

| Type | Retaining Part Shape | Dh7 | Threaded Selection | Screw Mounted 1mm Increment | Screw Mounted | |||||||||||||||||

| Hardened (Round) HATA (Diamond) HATD | Carburized (Round) THATA (Diamond) THATD | Dicoat (Round) D-HATA (Diamond) D-HATD | N (Threaded) T (Set Screw) B (Screw Mounted) | 6 | 0 -0.015 | 3.0~7.0 | 5~30 (B≤P×4) | 5 | 8 | 10 | - | 6 | 8 | 8 | 4 | M5 | - | 9 | 1 | 1(2) | ||

| 8 | 3.0~9.0 | 5 | 8 | 10 | 12 | 15 | 12~20 | 10 | 8 | 8 | 5 | M5 | M4 | 11 | 1 | 1(2) | ||||||

| 10 | 4.5~12.0 | (5) | (8) | 10 | 12 | 15 | 15~30 | 12 | 10 | 8 | 7 | M6 | M5 | 13 | 1 | 1~3 | ||||||

| 10T | 4.5~12.0 | (5) | (8) | 10 | 12 | 15 | 15~30 | 18 | 5 | 8 | 7 | M6 | M6 | 13 | 1 | 1~3 | ||||||

| 12 | 0 -0.018 | 9.0~13.0 | (8) | 10 | 12 | 15 | 18 | 15~30 | 15 | 12 | 10 | 9 | M8 | M5 | 15 | 1 | 4 | |||||

| 16 | 13.0~16.0 | (10) | 12 | 15 | 18 | 20 | 20~40 | 18 | 12 | 10 | 13 | M8 | M8 | 19 | 2 | 5 | ||||||

Alterations

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number | Minimum order quantity | Volume Discount | RoHS | Inlet Side Tip Shape | Mounting Side Shape | Material | Mounting Side Dia. D (Ø) | Heat Treatment | Concentricity | Insertion Guide Section Outer Dia. P (Ø) | Mounting Section Length L (mm) | Positioning Part Length B (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 7 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 3 ~ 8 | 5 ~ 10 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 3 ~ 10 | 5 ~ 15 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 4.5 ~ 12 | 10 ~ 15 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 4.5 ~ 12 | 10 ~ 15 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 9 ~ 14 | 10 ~ 18 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 13 ~ 18 | 12 ~ 20 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 3 ~ 8 | - | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 3 ~ 10 | - | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 4.5 ~ 12 | - | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 4.5 ~ 12 | - | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 9 ~ 14 | - | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 13 ~ 18 | - | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 3 ~ 8 | 5 ~ 10 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 3 ~ 10 | 5 ~ 15 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 4.5 ~ 12 | 10 ~ 15 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 4.5 ~ 12 | 10 ~ 15 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 9 ~ 14 | 10 ~ 18 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 13 ~ 18 | 12 ~ 20 | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 3 ~ 8 | - | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 3 ~ 10 | - | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 4.5 ~ 12 | - | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 4.5 ~ 12 | - | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 9 ~ 14 | - | 5 ~ 30 | ||

| 1 | 7 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated) | 13 ~ 18 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Screw Mounted (Tapped) | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | Standard Grade Ø0.03 | 3 ~ 10 | 12 ~ 20 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Screw Mounted (Tapped) | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | 15 ~ 30 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Screw Mounted (Tapped) | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | 15 ~ 30 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Screw Mounted (Tapped) | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | Standard Grade Ø0.03 | 9 ~ 14 | 15 ~ 30 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Screw Mounted (Tapped) | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | Standard Grade Ø0.03 | 13 ~ 18 | 20 ~ 40 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | Standard Grade Ø0.03 | 3 ~ 8 | 5 ~ 10 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | Standard Grade Ø0.03 | 3 ~ 10 | 5 ~ 12 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | 5 ~ 12 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | 5 ~ 12 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | Standard Grade Ø0.03 | 9 ~ 14 | 8 ~ 12 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Threads | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | Standard Grade Ø0.03 | 13 ~ 18 | 10 ~ 12 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | Standard Grade Ø0.03 | 3 ~ 8 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | Standard Grade Ø0.03 | 3 ~ 10 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | Standard Grade Ø0.03 | 9 ~ 14 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Round | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | Standard Grade Ø0.03 | 13 ~ 18 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Screw Mounted (Tapped) | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | Standard Grade Ø0.03 | 3 ~ 10 | 12 ~ 20 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Screw Mounted (Tapped) | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | 15 ~ 30 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Screw Mounted (Tapped) | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | 15 ~ 30 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Screw Mounted (Tapped) | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | Standard Grade Ø0.03 | 9 ~ 14 | 15 ~ 30 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Screw Mounted (Tapped) | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | Standard Grade Ø0.03 | 13 ~ 18 | 20 ~ 40 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | Standard Grade Ø0.03 | 3 ~ 8 | 5 ~ 10 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | Standard Grade Ø0.03 | 3 ~ 10 | 5 ~ 12 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | 10 ~ 12 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | 10 ~ 12 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | Standard Grade Ø0.03 | 9 ~ 14 | 10 ~ 12 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Threads | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | Standard Grade Ø0.03 | 13 ~ 18 | 12 | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | Standard Grade Ø0.03 | 3 ~ 8 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | Standard Grade Ø0.03 | 3 ~ 10 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | Standard Grade Ø0.03 | 4.5 ~ 12 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | Standard Grade Ø0.03 | 9 ~ 14 | - | 5 ~ 30 | ||

| 1 | 12 Days | 10 | Diamond | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | Standard Grade Ø0.03 | 13 ~ 18 | - | 5 ~ 30 |

Loading...

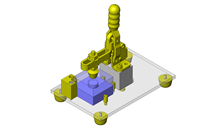

Basic information

| Basic Shape | Pins for Fixtures - Shouldered | Inlet Side Tip Type | Bullet Nose | Inlet Side Tolerance | Standard Grade 0/-0.05 |

|---|

Configure

Basic Attributes

-

Inlet Side Tip Shape

-

Round

Round -

Diamond

Diamond

-

-

Mounting Side Shape

-

Threads

Threads -

Circumference Groove (Set Screw)

Circumference Groove (Set Screw) -

Screw Mounted (Tapped)

Screw Mounted (Tapped)

-

-

Material

- Steel

- Steel

-

Mounting Side Dia. D(Ø)

-

Concentricity

- Standard Grade Ø0.03

- Standard Grade Ø0.05 (Dicoat Treated, TiCN Treated)

-

Insertion Guide Section Outer Dia. P(Ø)

-

Mounting Section Length L(mm)

-

Positioning Part Length B(mm)

-

Type

- D-HATAN

- D-HATAT

- D-HATDN

- D-HATDT

- HATAB

- HATAN

- HATAT

- HATDB

- HATDN

- HATDT

- THATAB

- THATAN

- THATAT

- THATDB

- THATDN

- THATDT

-

Heat Treatment

- Directly Quenched

- Carburized

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 7 Days or Less

- 12 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

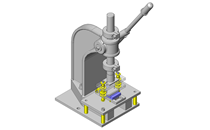

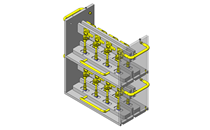

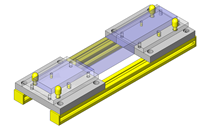

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry

![[Precision] X-Axis / Cross Roller](http://content.misumi-ec.com/image/upload/f_auto,t_product_recommend_a/v1/p/jp/product/series/110300196460/110300196460_001.jpg)