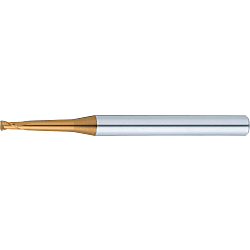

TSC series carbide tapered neck radius end mill, 2-flute / tapered neck model

- Volume Discount

-Suppresses chattering with a short flute length and a tapered shape at the peripheral edge

-It has a coating with high oxidation resistance and high hardness, and achieves a long service life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.

- TS

- General Steel

- 2 Flutes

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

| Part Number | Minimum order quantity | Volume Discount | Outer Diameter (D) (φ) | R Size (mm) | Work Material | Flute Length (ℓ) (mm) | Overall Length (L) (mm) | Shank Diameter (d) (mm) | Length Under Neck (ℓ1) (mm) | R Precision (μm) | Additional Classification | Neck Gradient (Degree) | #6 | #7 | Figure | Under Neck Diameter d1 (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 8 Days | 1 | 0.1 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 2 | 40 | 4 | - | ±0.01 | Manufactured Product | - | 3 ~ 5 | 7 ~ 19 | 2 | - | ||

| 1 | 8 Days | 1 | 0.2 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 2 | 40 | 4 | - | ±0.01 | Manufactured Product | - | 3 ~ 5 | 7 ~ 19 | 2 | - | ||

| 1 | 8 Days | 1 | 0.3 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 2 | 40 | 4 | - | ±0.01 | Manufactured Product | - | 3 ~ 5 | 7 ~ 19 | 2 | - | ||

| 1 | 8 Days | 1.5 | 0.1 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 3 | 40 | 4 | - | ±0.01 | Manufactured Product | - | 3 ~ 5 | 8 ~ 20 | 2 | - | ||

| 1 | 8 Days | 1.5 | 0.2 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 3 | 40 | 4 | - | ±0.01 | Manufactured Product | - | 3 ~ 5 | 8 ~ 20 | 2 | - | ||

| 1 | 8 Days | 1.5 | 0.3 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 3 | 40 | 4 | - | ±0.01 | Manufactured Product | - | 3 ~ 5 | 8 ~ 20 | 2 | - | ||

| 1 | 8 Days | 2 | 0.1 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 4 | 40 | 4 | - | ±0.01 | Manufactured Product | - | 0.5 ~ 5 | 9 ~ 21 | 2 | - | ||

| 1 | 8 Days | 2 | 0.2 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 4 | 40 | 4 | - | ±0.01 | Manufactured Product | - | 0.5 ~ 5 | 9 ~ 21 | 2 | - | ||

| 1 | 8 Days | 2 | 0.3 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 4 | 40 | 4 | - | ±0.01 | Manufactured Product | - | 0.5 ~ 5 | 9 ~ 21 | 2 | - | ||

| 1 | 8 Days | 2 | 0.5 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 4 | 40 | 4 | - | ±0.01 | Manufactured Product | - | 0.5 ~ 5 | 9 ~ 21 | 2 | - | ||

| 1 | 8 Days | 3 | 0.1 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 6 | 45 | 6 | - | ±0.01 | Manufactured Product | - | 0.5 ~ 5 | 11 ~ 21 | 2 | - | ||

| 1 | 8 Days | 3 | 0.2 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 6 | 45 | 6 | - | ±0.01 | Manufactured Product | - | 0.5 ~ 5 | 11 ~ 21 | 2 | - | ||

| 1 | 8 Days | 3 | 0.3 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 6 | 45 | 6 | - | ±0.01 | Manufactured Product | - | 0.5 ~ 5 | 11 ~ 21 | 2 | - | ||

| 1 | 8 Days | 3 | 0.5 | General Steel[◎] / Heat-Treated Steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum Alloy[○] / Copper Alloy[○] | 6 | 45 | 6 | - | ±0.01 | Manufactured Product | - | 0.5 ~ 5 | 9 ~ 15 | 2 | - |

Loading...

Specifications

Model Number

TSC-REM2PB (Stocked Product)

| Outer Diameter D |

Neck Gradient θ1 |

Length Under Neck ℓ1 |

Radius R |

Under Neck Diameter d1 |

Flute Length ℓ |

Overall Length L |

Shank Diameter d |

Figure |

| 0.2 | 1° | 1 | 0.05 | 0.22 | 0.16 | 50 | 4 | 1 |

| 2 | 0.26 | |||||||

| 3° | 1 | 0.26 | ||||||

| 2 | 0.37 | |||||||

| 5° | 1 | 0.30 | ||||||

| 2 | 0.48 | |||||||

| 0.3 | 1° | 2 | 0.05 | 0.35 | 0.24 | 50 | 4 | 1 |

| 3 | 0.38 | |||||||

| 3° | 2 | 0.45 | ||||||

| 3 | 0.55 | |||||||

| 5° | 2 | 0.54 | ||||||

| 3 | 0.72 | |||||||

| 0.4 | 1° | 3 | 0.05 0.1 | 0.48 | 0.28 | 50 | 4 | 1 |

| 4 | 0.51 | |||||||

| 3° | 3 | 0.63 | ||||||

| 4 | 0.74 | |||||||

| 5° | 3 | 0.78 | ||||||

| 4 | 0.96 | |||||||

| 0.5 | 1° | 3 | 0.05 0.1 | 0.57 | 0.32 | 50 | 4 | 1 |

| 5 | 0.64 | |||||||

| 8 | 0.74 | |||||||

| 10 | 0.81 | |||||||

| 12 | 0.88 | |||||||

| 3° | 3 | 0.71 | ||||||

| 5 | 0.92 | |||||||

| 8 | 1.23 | |||||||

| 10 | 1.44 | |||||||

| 12 | 1.65 | |||||||

| 5° | 3 | 0.85 | ||||||

| 5 | 1.20 | |||||||

| 8 | 1.72 | |||||||

| 10 | 2.07 | |||||||

| 0.8 | 1° | 5 | 0.05 0.1 0.2 | 0.92 | 0.64 | 50 | 4 | 1 |

| 8 | 1.02 | |||||||

| 3° | 5 | 1.16 | ||||||

| 8 | 1.47 | |||||||

|

1 |

1° | 6 | 0.05 0.1 0.2 0.3 | 1.14 | 0.8 | 50 | 4 | 1 |

| 10 | 1.28 | |||||||

| 15 | 1.45 | |||||||

| 20 | 1.63 | 70 | ||||||

| 25 | 1.80 | |||||||

| 30 | 1.98 | |||||||

| 35 | 2.15 | 100 | ||||||

| 3° | 6 | 1.42 | 50 | |||||

| 10 | 1.84 | |||||||

|

1.5 |

1° | 10 | 0.1 0.2 0.3 | 1.74 | 1.2 | 50 | 4 | 1 |

| 15 | 1.92 | |||||||

| 20 | 2.09 | 70 | ||||||

| 25 | 2.27 | |||||||

| 30 | 2.44 | |||||||

| 3° | 10 | 2.23 | 50 | |||||

| 15 | 2.76 | |||||||

|

2 |

1° | 15 | 0.1 0.2 0.3 0.5 | 2.38 | 1.6 | 50 | 4 | 1 |

| 20 | 2.56 | 70 | ||||||

| 25 | 2.73 | |||||||

| 30 | 2.91 | |||||||

| 40 | 3.26 | 100 | ||||||

| 50 | 3.61 | |||||||

| 3° | 15 | 3.15 | 50 | |||||

| 20 | 3.68 | 70 | ||||||

|

3 |

1° | 15 | 0.2 0.5 | 3.31 | 2.4 | 70 | 6 | 2 |

| 20 | 3.49 | |||||||

| 30 | 3.84 | |||||||

| 40 | 4.19 | 100 | ||||||

| 50 | 4.54 | |||||||

| 60 | 4.89 |

Model Number

TN-TSC-CR-EM2S (Manufactured Product)

| Outer Diameter D |

Radius R |

Neck Gradient θ1 0.5° Increment Designation |

Length Under Neck ℓ1 1 mm Increment Designation |

Under Neck Diameter d1 |

Flute Length ℓ |

Overall Length L |

Shank Diameter d |

Figure |

|

1 |

0.1 0.2 0.3 | 2.5° ~ 5° | 7 ~ 19 | - | 2 | 40 | 4 | 2 |

|

1.5 |

0.1 0.2 0.3 | 2.5° ~ 3° | 8 ~ 20 | - | 3 | 40 | 4 | 2 |

| 0.1 0.2 0.3 | 3.5° ~ 5° | 8 ~ 17 | - | |||||

|

2 |

0.1 0.2 0.3 0.5 | 0.5° ~ 3° | 9 ~ 21 | - | 4 | 40 | 4 | 2 |

| 0.1 0.2 0.3 0.5 | 3.5° ~ 5° | 9 ~ 15 | - | |||||

|

3 |

0.1 0.2 0.3 0.5 | 0.5° ~ 5° | 9 ~ 15 | - | 6 | 45 | 6 | 2 |

[ ! ]When ordering manufactured products, be sure to refer to an ordering example as the points below differ from when ordering a stocked product.

(1) "TN-" is prepended to the start of the model number. (2) "S" is appended to the end of the model number. (3) The order for specifying the "radius" differs from that of stocked products.

For Cutting Conditions, Refer to >>Click here.

More Information

● It adopts a short flute length and back-tapered peripheral cutting edge for suppressing chatter.

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, yielding a longer operational life and is ideal for high speed machining / dry machining.

Basic information

| Number of Flutes(sheet) | 2 | Model | Tapered Neck Radius | Processing Applications | Flat Surface / Side Surface / Curved Surface / Groove / Inclined Cutting |

|---|---|---|---|---|---|

| Coating | For High Hardness (Silicone-Based) | Torsion Angle (θ) | Standard Helix (30 to 40°) |

Configure

Basic Attributes

-

Outer Diameter (D)(φ)

-

R Size(mm)

-

Work Material

- General Steel

- Heat-Treated Steel

- High-Hardness Steel ~ HRC55

- Stainless Steel

- Cast Iron

- Aluminum Alloy

- Copper Alloy

-

Flute Length (ℓ)(mm)

-

Overall Length (L)(mm)

-

Shank Diameter (d)(mm)

-

Length Under Neck (ℓ1)(mm)

-

Additional Classification

- Manufactured Product

- Stocked Product

-

Neck Gradient(Degree)

- 1

- 3

- 5

-

#6

-

#7

-

Type

- TN-TSC-CR-EM2S

- TSC-REM2PB

-

R Precision(μm)

Filter by standard shipping days

-

- All

- 5 Days or Less

- 8 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .