Bekräftad

- Work Material

- Material - Carbide Coating

- Type

- Uppskattade leveransdagar

- Alla

- Inom 5 arbetsdagar

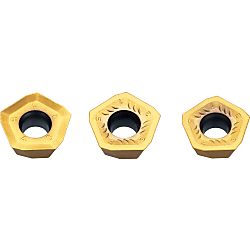

High-Feed Radius Cutter (5-Corner Model), Tip

Skiss

Detaljerad information

Grundläggande information

Stable processing is made possible by the geometry and tip material that have the excellent cutting performance

Specifikationer och pris

Specifications

| Model Number | Breaker | Material | ℓ | d | s | d1 | m | b | r |

| Carbide Coating | |||||||||

| PDMX0905ZE | 51 | KR5020 | 9 | 13.5 | 5.47 | 5.5 | 0.545 | 2 | 0.8 |

| 81 | KR5020 | ||||||||

| PR5040 |

Material information >>Click here.

Funktioner och användningsexempel

More Information

● Breaker / Material Selection Criteria| Breaker Shape | Material | Tip Characteristics |

| 51 | KR5020 | Suitable for high-speed machining, semi-finishing. Ideal for carbon steel / alloy steel, stainless steel, and heat-resistant alloy. Can also be used for cast iron, non-ferrous metals, and high-hardness steel. |

| 81 | KR5020 | For standard rough machining. Ideal for carbon steel / alloy steel, stainless steel, and cast iron. Can also be used for high-hardness steel. |

| PR5040 | Suitable for rough machining and heavy cutting under severe conditions, such as when a long protrusion is required. Specializes in carbon steel / alloy steel, and stainless steel. Can also be used for high-hardness steel. |

Artikelnumret har bekräftats