Servo couplings / hub clamping / 1 disc: PI / body: aluminium / FSKK / ABP Antriebstechnik

- Promotional pricing ends 30/11/2024

- Volume Discount

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

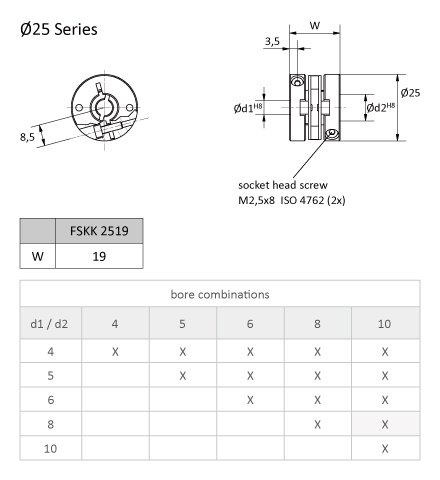

FSKK 2519

Part No. Example: FSKK 2519 08/10

(Series ØW d1/d2)

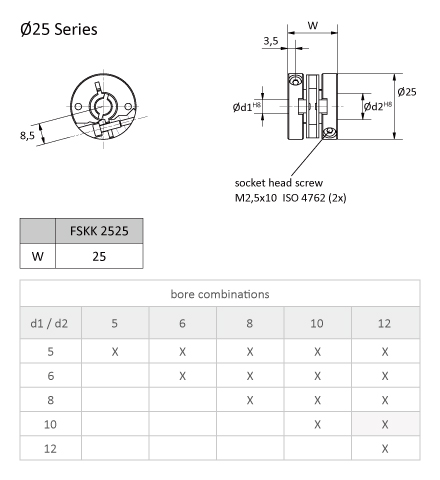

FSKK 2525

Part No. Example: FSKK 2525 10/12

(Series ØW d1/d2)

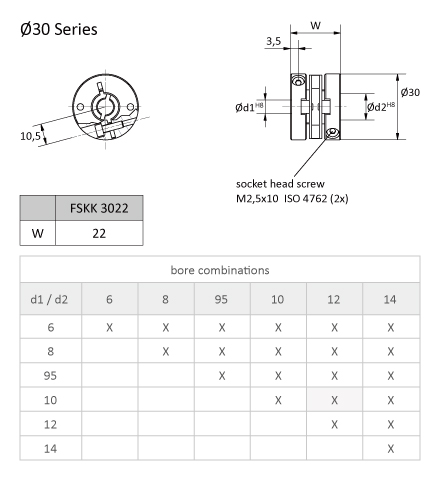

FSKK 3022

Part No. Example: FSKK 3022 10/12

(Series ØW d1/d2)

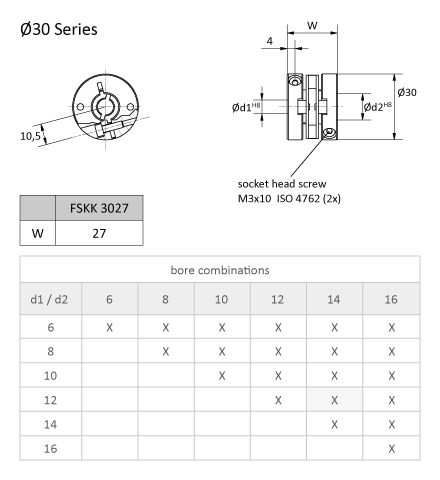

FSKK 3027

Part No. Example: FSKK 3027 12/14

(Series ØW d1/d2)

Part Number

|

|---|

| FSKK 2525 08/08 |

| FSKK 2525 10/10 |

| FSKK 3022 95/95 |

| FSKK 3027 06/06 |

| FSKK 3027 08/10 |

| FSKK 3027 08/12 |

| FSKK 3027 08/16 |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | Shaft Bore Dia. (machined) D1 (mm) | Shaft Bore Dia. (machined) D2 (mm) | Outer Dia. A (mm) | Overall Length W (mm) | Allowable Torque (Nm) | Allowable Lateral Misalignment (mm) | Allowable Angular Misalignment (deg) | Allowable Axial Clearance (±) (mm) | Moment of Inertia (g・cm2) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

41.75 € | 1 | Available | 3 Days | 8 | 8 | 25 | 25 | 0.65 | ±0.3 | ±2.5 | 0.4 | 2.1 | |

41.75 € | 1 | Available | 3 Days | 10 | 10 | 25 | 25 | 0.65 | ±0.3 | ±2.5 | 0.4 | 2.9 | |

43.75 € | 1 | Available | 3 Days | 9.52 | 9.52 | 30 | 22 | 1.2 | ±0.3 | ±2.5 | 0.4 | 2.1 | |

43.75 € | 1 | Available | 3 Days | 6 | 6 | 30 | 27 | 1.2 | ±0.3 | ±2.5 | 0.4 | 2.8 | |

43.75 € | 1 | Available | 3 Days | 8 | 10 | 30 | 27 | 1.2 | ±0.3 | ±2.5 | 0.4 | 37 | |

43.75 € | 1 | Available | 3 Days | 8 | 12 | 30 | 27 | 1.2 | ±0.3 | ±2.5 | 0.2 | 2.5 | |

43.75 € | 1 | Available | 3 Days | 8 | 16 | 30 | 27 | 1.2 | ±0.3 | ±2.5 | 0.4 | 22.2 |

Loading...

Technical Information

| Technical data | FSKK 2519 | FSKK 2525 | FSKK 3022 | FSKK 3027 | |

|---|---|---|---|---|---|

| Max. speed | min-1 | 12.000 | 12.000 | 12.000 | 12.000 |

| Max. torque | Ncm | 40 | 40 | 60 | 60 |

| Max. offset off shafts | |||||

| Radial | mm | ± 0,25 | ± 0,25 | ± 0,3 | ± 0,3 |

| Axial | mm | ± 0,4 | ± 0,4 | ± 0,4 | ± 0,4 |

| Angular | Grad | ± 2,5 | ± 2,5 | ± 2,5 | ± 2,5 |

| Torsion spring stiffness | Nm/rad | 22 | 22 | 30 | 30 |

| Radial spring stiffness | N/mm | 60 | 60 | 40 | 40 |

| Moment of inertia | gcm2 | 13,5 | 15 | 35 | 37 |

| Max. clamping torque (M) | Ncm | 65 | 65 | 120 | 120 |

| Temperature range | °C | -10 to +80 | |||

| Weight appr. | g | 16 | 18 | 30 | 32 |

| Material | Flange | Aluminium, anodised | |||

| Material | Membrane | Polyamid 6.6, fiberglas reinforced | |||

M = tightening torque of the clamping screw

Because of the material properties of plastic, a dimensional deviation of up to 0.5 mm can occur in the length.

Basic information

| Type | Disc Type | Allowable Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Application | Standard / Servo Motor / Stepping Motor / Encoder |

|---|---|---|---|---|---|

| Allowable Torque Range(N•m) | 0.05 to 1.00 | Max. Rotational Speed Range(r/min) | 10,001 to 78,000 | Feature | High Durability / Low Moment of Inertia / Vibration Insulation / Small / Clean Environment |

| Body Material | Aluminum | Max. Rotational Speed(r/min) | 12000 | Allowable Lateral Misalignment Range(mm) | 0.21 to 0.40 |

| Disc Part Material | Polyimide | Operating Temperature Range(°C) | -10::80 |

Configure

Basic Attributes

-

Shaft Bore Dia. (machined) D1(mm)

-

Shaft Bore Dia. (machined) D2(mm)

-

Outer Dia. A(mm)

-

Overall Length W(mm)

-

Allowable Torque(Nm)

-

Allowable Lateral Misalignment(mm)

-

Moment of Inertia(g・cm2)

-

Type

- FSKK 2519

- FSKK 2525

- FSKK 3022

- FSKK 3027

-

Allowable Angular Misalignment(deg)

-

Filter by CAD data type

- 3D

Filter by standard shipping days

-

- All

- Same day

- 3 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .