Power Cables(Conductor Cross Section:2,5)

| Shipping Days |

|

|---|

?* Information on days to ship and prices

-

ÖLFLEX® HEAT 125 C MC

LAPP

Benefits

· Reduction of flame propagation, density and toxicity of smoke gases in event of fire

· Copper braiding screens the cable against electromagnetic interference

· For safety in areas with high density of people

· Certified\xa0for maritime applications

· Minimises damage to buildings and equipment caused by the formation of toxic acid fumes in fires

Application

· Coil winding, electromagnets, pumps, electrical systems

· For the wiring and connection of lighting, heating appliances, control cabinets, and distributors in mechanical and plant engineering

· Heat treatment plants, pressure die casting, heating and cooling technology

· For use in traffic regulation systems and outdoors

· For outdoor applications- Volume Discount

Configure nowStarting from∗ : 1,077.82 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

ÖLFLEX® SERVO 2YSLCY-JB

LAPP

Benefits

· Low-capacitance core insulation for long transmission paths

· Ideal protection against electromagnetic interference thanks to double screening made of aluminium-laminated foil and copper braided screening with a high degree of coverage

· Power supply for large electric drives possible

· Available as a 4-core variant and 3+3 balanced variant

· Versions with balanced cable design and three-part protective earth largely prevent the generation of harmful currents on the motor bearing A reduction in motor bearing damage contributes to the durability of electric motors

Application

· Suitable for medium mechanical stress

· For fixed installation and occasional flexing

· Can be used in dry, damp or wet environments

· The PVC outer sheath is resistant to acids and alkalis and has limited oil resistance

· Black variants are suitable for outdoor use, subject to the temperature range

· Flexible use at temperatures up to -15°C (ÖLFLEX® SERVO 2YSLCYK)

· For connecting frequency converters and motors- Volume Discount

Configure nowStarting from∗ : 267.23 € Min. Shipping Days : 8 Days *Unit price with basic configuration

-

ÖLFLEX® HEAT 125 MC

LAPP

Benefits

· For the protection of people and property

· Classified fire behaviour according to EU Directive 305/2011 (BauPVO/CPR) with article number selection on the LAPP website

· Halogen free and highly flame retardant materials reduce the risk of flame propagation, high smoke density and toxic flue gases in the event of a fire

· DNV approval for maritime use

· Suitable for voltage class 300/500 V

· Electron beam cross-linked insulating material enables use at low and high temperatures (-55°C to +125°C)

Application

· Suitable for medium mechanical stress

· Suitable for outdoor use

· For fixed installation and occasional flexing without tensile strain

· For universal use for wiring machine-internal and cross-plant control circuits

· Can be used in dry, damp and, especially, harsh and oily environments

· The electron beam cross-linked polymer compound is highly resistant to oils, fuels, alkalis and acids

· Flexible use at temperatures down to -35 °C

· Typical areas of application are heaters, switchgear, connection boxes, lighting, etc- Volume Discount

Configure nowStarting from∗ : 581.69 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

H07RN-F, enhanced version

LAPP

Benefits

· Tested for use underwater to a water depth of 100 m and a water temperature of 40°C

· Made according to harmonised European type H07RN-F, with ◁HAR▷ testing mark for proven reliability and quality

· Halogen free core insulation and sheath compound, as well as the confirmed low smoke emission in the event of a fire, make the cable suitable for use in public areas

· ◁HAR▷-style cables are widely accepted and can be used in Europe

· Extremely versatile in various applications and environments thanks to high-quality insulation and sheath materials and improved properties (compared to H07RN-F, normal version)

· Wider temperature range than usual for other rubber cables

· Single-core cables of this type can be used for short circuit-proof and short-to-ground-proof installation

Application

· Suitable for outdoor use

· For structured building cabling for fulfilling special fire protection requirements

· For flexible use

· Can be used in dry, wet and especially in harsh and oily environments

· Withstands heavy mechanical stress

· Flexible use at temperatures down to -40°C

· Cable design also suitable for torsion applications in wind turbines

· For connecting devices and machines to a power supply in various applications- Volume Discount

Configure nowStarting from∗ : 125.35 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

Configure now

Starting from∗ : 8.40 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

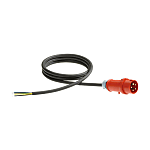

ÖLFLEX® PLUG CEE Connection/ Extension Cable without phase shifter*

LAPP

Application

· Machines and systems on building sites

· For connections to any three-phase AC consumers

· According to EN 50565-2: Dry or damp rooms as well as outdoors- Volume Discount

Configure nowStarting from∗ : 38.27 € Min. Shipping Days : 5 Days *Unit price with basic configuration

| Brand |

|---|

| Product Series |

| Starting from∗ |

| Min. Shipping Days |

| Overall Length(m) |

| Specified Length(m) |

| Conductor Cross Section(mm2) |

| Number Of Cores(Core) |

| Finished outer diameter(mm) |

| Sheath (outer coating) color |

| Sheath (outer coating) material |

| Insulation body materials |

| Brand | LAPP | LAPP | LAPP | LAPP | LAPP | LAPP |

|---|---|---|---|---|---|---|

| Product Series | ÖLFLEX® PLUG CEE Connection/ Extension Cable without phase shifter* | |||||

| Starting from∗ | 1,077.82 € *Unit price with basic configuration Volume Discount | 267.23 € *Unit price with basic configuration Volume Discount | 581.69 € *Unit price with basic configuration Volume Discount | 125.35 € *Unit price with basic configuration Volume Discount | 8.40 € *Unit price with basic configuration Volume Discount | 38.27 € *Unit price with basic configuration Volume Discount |

| Min. Shipping Days | 5 Days | 8 Days | 5 Days | 5 Days | 5 Days | 5 Days |

| Overall Length(m) | 100 ~ 500 | 50 ~ 1000 | 100 ~ 500 | 100 ~ 500 | 3 | 2,5 ~ 25 |

| Specified Length(m) | - | - | - | - | - | - |

| Conductor Cross Section(mm2) | 2,5 | 2,5 | 2,5 | 2,5 | 2,5 | 2,5 |

| Number Of Cores(Core) | 2 ~ 12 | 4 | 2 ~ 7 | 1 ~ 12 | 3 | 5 |

| Finished outer diameter(mm) | 10 ~ 19,3 | 12,4 | 9 ~ 13,2 | 7,9 ~ 21,8 | 11,4 | 17 |

| Sheath (outer coating) color | Black | Black | Black | Black | Black | Black |

| Sheath (outer coating) material | Polyester-Based | PVC (Polyvinyl Chloride) | Polyester-Based | Other | PVC (Polyvinyl Chloride) | PVC (Polyvinyl Chloride) |

| Insulation body materials | - | - | - | - | - | - |

Loading...

Filter by:

-

Overall Length(m)

-

Specified Length(m)

-

Conductor Cross Section(mm2)

-

Number Of Cores(Core)

-

Finished outer diameter(mm)

-

Sheath (outer coating) color

- Black

- Gray

- White

- Red

- Orange

- Yellow

- Other

- Other

-

Sheath (outer coating) material

- PVC (Polyvinyl Chloride)

- Polyester-Based

- Rubber-Based

- Other

-

Insulation body materials

- PVC (Polyvinyl Chloride)

Brand

CAD data type

-

- 2D

- 3D