Thread Cutters(Screw Types:Meter)

| Shipping Days |

|

|---|

?* Information on days to ship and prices

-

Configure now

Min. Shipping Days : 5 Days -

Configure now

Starting from∗ : 13.28 € Min. Shipping Days : 4 Days *Unit price with basic configuration

-

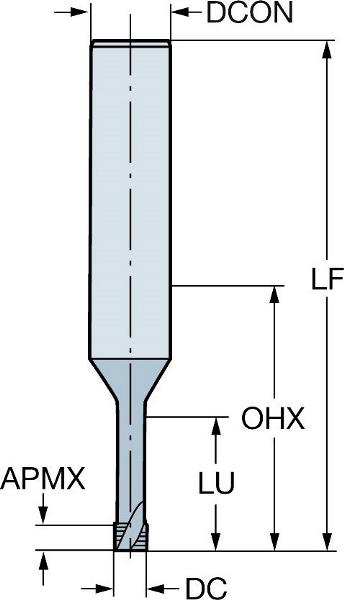

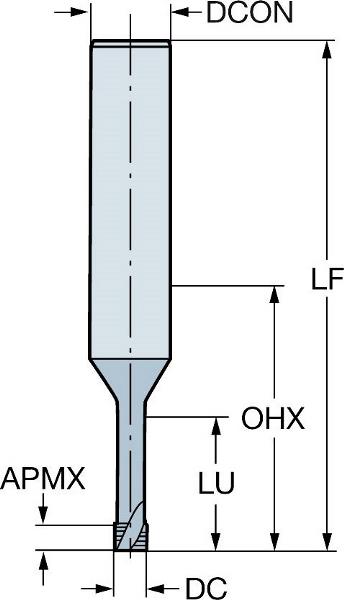

TiAlN Coated Carbide Threading Cutter, for Internal Metric Threads

MISUMI

Threading cutters that enable the high-speed stable processing are available at special prices- Volume Discount

Configure nowStarting from∗ : 110.87 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

DLC Coated Carbide Threading Cutter for Aluminum Machining, for Internal Metric Threads / 2D Model

MISUMI

[Features]

-Carbide thread cutter for stable high speed machining

-Can be used for both blind holes and through holes

-DLC coating with excellent abrasion resistance and chip weld resistance makes it ideal for non-steel metals such as aluminium and copper.- Volume Discount

Configure nowStarting from∗ : 113.79 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

TiAlN Coated Carbide Threading Cutter, for Internal Metric Threads

MISUMI

[Features]

-Thread cutting with small diameters from M1.4 × 0.3 (pilot hole diameter ø1.1 mm) is possible

-Reduced cutting load due to short flute length (3 webs)

-Enables effective thread cutting right into the corners of blind holes.- Volume Discount

Configure nowStarting from∗ : 181.78 € Min. Shipping Days : 7 Days *Unit price with basic configuration

-

Configure now

Starting from∗ : 87.75 € Min. Shipping Days : 4 Days *Unit price with basic configuration

-

Configure now

Starting from∗ : 5.27 € Min. Shipping Days : 3 Days *Unit price with basic configuration

-

Configure now

Starting from∗ : 252.00 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

TiAlN Coated Carbide Threading Cutter, for High-Hardness Steel / for Internal Metric Threads

MISUMI

The left-flute left-rotary cutting that's achieved by the original geometry and coating allow the milling threading of high hardness steel of up to HRC62.- Volume Discount

Configure nowStarting from∗ : 222.23 € Min. Shipping Days : 7 Days *Unit price with basic configuration

-

TS Coated Carbide Threading Cutter, for Internal Metric Threads

MISUMI

[Features]

--Tungsten carbide thread cutter for stable high speed machining

-Can be used for both blind holes and through holes

-

-It is coated with high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating characteristics.- Volume Discount

Configure nowStarting from∗ : 181.83 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

Planet Cutter Series Small Diameter Planet Cutters WH-VM-PNC

OSG

The planet cutter is able to mill M1 - M5 small diameter female screws. Ideal for Preventing Defects in High Value Added Manufactured Articles and for Tapping without a Pilot Hole Margin- Volume Discount

Configure nowStarting from∗ : 101.50 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

Planet Cutter Series MC-Planet Cutters PNGT

OSG

Different threads can be processed with the same pitch using a single piece. Both right-handed and left-handed threads can be processed.Configure nowStarting from∗ : 211.79 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

Planet Cutter Series NC-Planet Cutters WX-PNC

OSG

Different threads can be processed with the same pitch using a single piece. Both right-handed and left-handed threads can be processed.- Volume Discount

Configure nowStarting from∗ : 158.30 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

Planet Cutter Series Super Planet DR-PNAC

OSG

A Single Piece Can be Used as a Complex Tool, for Pilot Hole Drilling + Chamfering + Female Thread Processing, Reducing Unnecessary Non-Processing Time in Tool Changes and Improving ProductivityConfigure nowStarting from∗ : 295.75 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

Planet Cutter Series Super Planet with Oil Holes DR-O-PNAC

OSG

A Single Piece Can be Used as a Complex Tool, for Pilot Hole Drilling + Chamfering + Female Thread Processing, Reducing Unnecessary Non-Processing Time in Tool Changes and Improving ProductivityConfigure nowStarting from∗ : 324.46 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

Planet Cutter Series Planet Cutters with Oil Holes for Steel WXO-ST-PNC

OSG

By spraying machining oil compound from the lubrication hole, allows effective removal of cutting debris.Configure nowStarting from∗ : 165.90 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

Thread Cutter for Blind Hole / Through Hole TM SP for 2 X D 3737

GUHRING

[Features]

· Threading is performed with helical cutting.

· If the pitch is the same, one unit can process threads with different diameters.

· Both right-handed and left-handed female threads can be machined.Configure nowStarting from∗ : 254.77 € Min. Shipping Days : 8 Days *Unit price with basic configuration

-

Thread Cutter for Blind Hole / Through Hole TM SP for 2 X D 4133

GUHRING

[Features]

· Threading is performed with helical cutting.

· If the pitch is the same, one unit can process threads with different diameters.

· Both right-handed and left-handed female threads can be machined.Configure nowStarting from∗ : 196.80 € Min. Shipping Days : 8 Days *Unit price with basic configuration

-

MC - Helical Cutter MC-HLC

YAMAWA MFG

A screw processing tool that utilizes the "helical feed" function. Female threading of different diameters can be done with a single tool, provided the pitch is the same, and either right- or left-handed female screws can be machined.Configure nowStarting from∗ : 257.30 € Min. Shipping Days : 8 Days *Unit price with basic configuration

-

Carbide MC - Helical Cutter MC-CSLC

YAMAWA MFG

A screw processing tool that utilizes the "helical feed" function. Female threading of different diameters can be done with a single tool, provided the pitch is the same, and either right- or left-handed female screws can be machined.Configure nowStarting from∗ : 295.34 € Min. Shipping Days : 8 Days *Unit price with basic configuration

-

Carbide Solid Mill Thread Metric Screw (ISO)

CARMEX

Enables internal threading to be performed in a single pass.

[Features]

· Threading is done in 1 pass.

· Spiral grooves allow reduction of cutting torque and smoother processing.

· Machining time can be shortened with this multi-blade type, with flute count from 3 to 6.

· Starting with blade diameter of 2.2 mm, various small diameters are available.

· Can be used to cut the effective thread up to the edge of blind holes.

· The same tool can be used to machine workpieces of different materials.

· The finish is very clean.

· The unique multilayer coating extends the life of the tool.

· Cutting pressure is reduced, enabling machining of thin workpieces.

· The same tool can be used for left and right threading.Configure nowStarting from∗ : 229.39 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

Carbide Solid Mill Thread with Oil Hole ISO

CARMEX

Metric thread / for I.D.

[Features]

· Threading is done in 1 pass.

· Spiral grooves allow reduction of cutting torque and smoother processing.

· Machining time can be shortened with this multi-blade type, with flute count from 3 to 6.

· Starting with blade diameter of 2.2 mm, various small diameters are available.

· Can be used to cut the effective thread up to the edge of blind holes.

· The same tool can be used to machine workpieces of different materials.

· The finish is very clean.

· The unique multilayer coating extends the life of the tool.

· Cutting pressure is reduced, enabling machining of thin workpieces.

· The same tool can be used for left and right threading.Configure nowStarting from∗ : 229.39 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

MTZ Jet Mill Thread with Oil Hole ISO

CARMEX

For metric I.D. thread.

[Features]

· New type of carbide solid mill thread with oil holes inside the spiral groove.

· Efficiently conveys cooling fluid to the cutting edge for smoother machining.

· Especially effective with through holes.

· Effective for cutting powder removal.

· Also suitable for machinery that does not include an external lubricating device.Configure nowStarting from∗ : 263.46 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

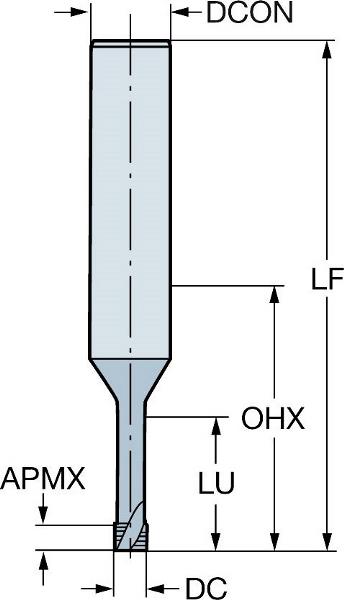

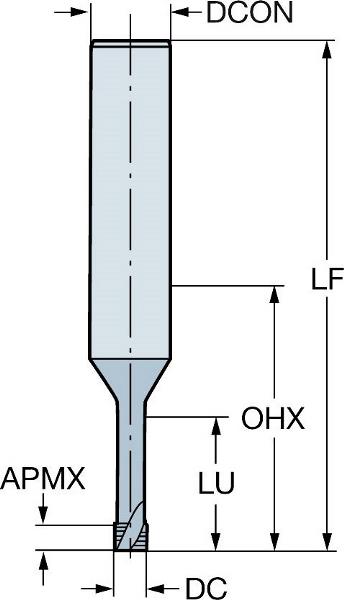

Neck Narrowed Q-Type, with Oil Hole for Inner Diameter Meter Threads

CARMEX

For internally threaded metric screws.

[Features]

· For thread cutting deep, large diameter holes.

· With neck thinly processed and an oil hole, it is suitable for screw-cutting deep holes of medium to thick diameters.

· Stable processing without causing chatter is possible.

· Deep hole drilling can be performed with one pass.

· Blade length is shorter, so cutting resistance decreases.

· Able to thread long blade lengths of up to 3DConfigure nowStarting from∗ : 349.53 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

Carbide Solid for Outer Diameter, Mill Thread ISO

CARMEX

Metric thread / for O.D. thread.

[Features]

· The spiral blade enables a clean finish.

· Machining time is reduced by using three to six flutesConfigure nowStarting from∗ : 342.45 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

Carbide Solid Mill Thread, No Finishing Flute 60°

CARMEX

It is made of MT8 material with new three-layer PVD coating on ultra-fine particle carbide, and is effective for threading deep holes for both internal and outer diameter threads.Configure nowStarting from∗ : 208.53 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

DMT 3in1 ISO Internal Diameter Metric Thread 60° with Internal Lubrication Hole

CARMEX

With internal coolant hole, up to screw depth D1 x 2.

[Features]

· 3 functions with one tool. (drilling + threading + chamfering).

· Thanks to the circular arc helical machining, thread cutting, chamfering and drilling are completed in one step.

· Drilling tools are not required.

· High-performance tools shorten the cycle time and reduce the machining costs.

· Can be used for both blind holes and through holes.

· Because one tool can be used for drilling, threading, and chamfering, less time is spent replacing tools.

· Thread processing with finished blade can be performed.

· Both right-handed and left-handed threads can be processed with the same tool.Configure nowStarting from∗ : 298.23 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

Hard Cut ISO

CARMEX

[Features]

· This new tool meets the needs of the mold industry.

· High-speed cutting enabled.

· Shortens the machining time.

· The blade length is short, so cutting load is not applied.

· Can be used to cut the effective thread up to the edge of blind holes.Configure nowStarting from∗ : 244.68 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

Slim Head Type Hard Cut MTH ISO

CARMEX

[Features]

· For mini mill thread type hard cuts, we have developed an innovative tool capable of threading high hardness materials up to HRC 62 in one pass.

· Shortens machining time because the same tool can be used for thread cutting and chamfering.

· Compatible with relatively large diameters.

· The unique coating technology demonstrates excellent resistance to abrasion and heat.

· Excellent carbide grade which also handles hardened steel.

· Cutting chips are reduced, providing machining stability.

· The cycle time is short, increasing productivity.

· Supports screw depths up to twice the machining thread diameter.Configure nowStarting from∗ : 266.94 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

MTI Mini Mill Thread, w / o Finishing Teeth, for Both 60° Inner / Outer Diameters

CARMEX

For both internal and external threading

[Features]

· Ultrafine particle carbide and new type three-layer PVD coatingConfigure nowStarting from∗ : 208.52 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

MTI Mini Mill Thread, w / o Finishing Teeth, for Both 55° Inner / Outer Diameters

CARMEX

For both internal and external threading

[Features]

· Ultra-fine particle carbide with an advanced three layer PVD blue coatingConfigure nowStarting from∗ : 208.52 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

MTI Mini Mill Thread ISO, for Meter Screws and Inner-Diameter Screws

CARMEX

Metric thread / for I.D. thread

[Features]

· Ultra-fine particle carbide with an advanced three layer PVD blue coatingConfigure nowStarting from∗ : 212.85 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

Hard Cut ISO

CARMEX

Now with further improved cutting performance and beautiful surface finishing.

[Features]

· Lineup starting from the very small diameter of M1.4 x 0.3 is available.

· This new tool meets the needs of the mold industry.

· High-speed cutting enabled.

· Shortens the machining time.

· The blade length is short, so cutting load is not applied.

· Can be used to cut the effective thread up to the edge of blind holes.Configure nowStarting from∗ : 390.43 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

Configure now

Starting from∗ : 128.63 € Min. Shipping Days : 8 Days *Unit price with basic configuration

-

Configure now

Starting from∗ : 7.75 € Min. Shipping Days : 4 Days *Unit price with basic configuration

-

Configure now

Starting from∗ : 68.00 € Min. Shipping Days : 4 Days *Unit price with basic configuration

| Brand |

|---|

| Product Series |

| Starting from∗ |

| Min. Shipping Days |

| Screw Types |

| Screw size (Nominal) |

| Pitch (P), Number of Threading(mm) |

| Tool Material Type |

| work material |

| Tap Type |

| Hole type |

| Coating Y/N |

| Coating Type |

| Overall Length (L)(mm) |

| Brand | SANDVIK | WERA | MISUMI | MISUMI | MISUMI | WERA | RUKO | SANDVIK | MISUMI | MISUMI | OSG | OSG | OSG | OSG | OSG | OSG | GUHRING | GUHRING | YAMAWA MFG | YAMAWA MFG | CARMEX | CARMEX | CARMEX | CARMEX | CARMEX | CARMEX | CARMEX | CARMEX | CARMEX | CARMEX | CARMEX | CARMEX | CARMEX | YAMAWA MFG | WERA | WERA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Series | SANDVIK CoroMill Plura Solid Carbide End Mill for Thread Milling | TiAlN Coated Carbide Threading Cutter, for Internal Metric Threads | DLC Coated Carbide Threading Cutter for Aluminum Machining, for Internal Metric Threads / 2D Model | TiAlN Coated Carbide Threading Cutter, for Internal Metric Threads | TiAlN Coated Carbide Threading Cutter, for High-Hardness Steel / for Internal Metric Threads | TS Coated Carbide Threading Cutter, for Internal Metric Threads | Planet Cutter Series Small Diameter Planet Cutters WH-VM-PNC | Planet Cutter Series Planet Cutters with Oil Holes for Steel WXO-ST-PNC | Thread Cutter for Blind Hole / Through Hole TM SP for 2 X D 3737 | Thread Cutter for Blind Hole / Through Hole TM SP for 2 X D 4133 | Neck Narrowed Q-Type, with Oil Hole for Inner Diameter Meter Threads | DMT 3in1 ISO Internal Diameter Metric Thread 60° with Internal Lubrication Hole | MTI Mini Mill Thread, w / o Finishing Teeth, for Both 60° Inner / Outer Diameters | MTI Mini Mill Thread, w / o Finishing Teeth, for Both 55° Inner / Outer Diameters | MTI Mini Mill Thread ISO, for Meter Screws and Inner-Diameter Screws | |||||||||||||||||||||

| Starting from∗ | - | 13.28 € *Unit price with basic configuration Volume Discount | 110.87 € *Unit price with basic configuration Volume Discount | 113.79 € *Unit price with basic configuration Volume Discount | 181.78 € *Unit price with basic configuration Volume Discount | 87.75 € *Unit price with basic configuration Volume Discount | 5.27 € *Unit price with basic configuration Volume Discount | 252.00 € *Unit price with basic configuration | 222.23 € *Unit price with basic configuration Volume Discount | 181.83 € *Unit price with basic configuration Volume Discount | 101.50 € *Unit price with basic configuration Volume Discount | 211.79 € *Unit price with basic configuration | 158.30 € *Unit price with basic configuration Volume Discount | 295.75 € *Unit price with basic configuration | 324.46 € *Unit price with basic configuration | 165.90 € *Unit price with basic configuration | 254.77 € *Unit price with basic configuration | 196.80 € *Unit price with basic configuration | 257.30 € *Unit price with basic configuration | 295.34 € *Unit price with basic configuration | 229.39 € *Unit price with basic configuration | 229.39 € *Unit price with basic configuration | 263.46 € *Unit price with basic configuration | 349.53 € *Unit price with basic configuration | 342.45 € *Unit price with basic configuration | 208.53 € *Unit price with basic configuration | 298.23 € *Unit price with basic configuration | 244.68 € *Unit price with basic configuration | 266.94 € *Unit price with basic configuration | 208.52 € *Unit price with basic configuration | 208.52 € *Unit price with basic configuration | 212.85 € *Unit price with basic configuration | 390.43 € *Unit price with basic configuration | 128.63 € *Unit price with basic configuration | 7.75 € *Unit price with basic configuration Volume Discount | 68.00 € *Unit price with basic configuration Volume Discount |

| Min. Shipping Days | 5 Days | 4 Days | 5 Days | 5 Days | 7 Days | 4 Days | 3 Days | 5 Days | 7 Days | 5 Days | 6 Days | 6 Days | 6 Days | 6 Days | 6 Days | 6 Days | 8 Days | 8 Days | 8 Days | 8 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 8 Days | 4 Days | 4 Days |

| Screw Types | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter |

| Screw size (Nominal) | M1.6 ~ MF28 | M3 ~ M10 | M3 ~ M20 | M3 ~ M16 | M1.4 ~ M20 | - | M2 | M10 | M2 ~ M12 | M3 ~ M12 | - | - | - | M6 ~ M12 | M6 ~ M12 | - | M6 ~ M20 | M6 ~ M20 | 1020N100M ~ 32506N300M | 035083N075M ~ 200505N300M | M3 ~ M27 | M4 ~ M24 | M6 ~ M20 | - | - | - | - | - | M3 ~ M12 | - | - | M1 ~ M3 | - | 3.5 ~ 9 | M3 ~ M10 | - |

| Pitch (P), Number of Threading(mm) | 0.5 ~ 3 | - | 0.5 ~ 2.5 | 0.5 ~ 2 | 0.3 ~ 2.5 | - | - | - | 0.4 ~ 1.75 | 0.5 ~ 1.75 | 0.25 ~ 0.8 | 1 ~ 3.5 | 1 ~ 3 | 1 ~ 1.75 | 1 ~ 1.75 | 0.5 ~ 3 | 1 ~ 2.5 | 1 ~ 2.5 | - | 0.5 ~ 3 | 0.5 ~ 3 | 0.5 ~ 3 | 1 ~ 2.5 | 1 ~ 4 | 1 ~ 2 | - | 1 ~ 2 | 0.4 | 0.5 ~ 1.75 | - | - | 0.25 ~ 0.5 | 2 | 1 | - | - |

| Tool Material Type | - | - | Carbide | Carbide | Carbide | - | High-speed steel | - | Carbide | Carbide | Carbide | Cobalt HSS | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Cobalt HSS | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | Carbide | - | - |

| work material | - | - | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / High Carbon Steel (C with a content over 0.45%)[◎] / Alloy Steel (SCM)[◎] / Stainless Steel (JIS-SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Quenched and tempered steel (35 to 45 HRC)[○] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] | Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[◎] / Aluminum Rolled Material (AL)[◎] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / High Carbon Steel (C with a content over 0.45%)[◎] / Alloy Steel (SCM)[◎] / Stainless Steel (JIS-SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] | - | - | - | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[◎] / Quenched and tempered steel (35 to 45 HRC)[◎] / Quenched and tempered steel (45 to 55 HRC)[◎] / High Hardness Steel (50-60 HRC)[◎] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / High Carbon Steel (C with a content over 0.45%)[◎] / Alloy Steel (SCM)[◎] / Stainless Steel (JIS-SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / High Hardness Steel (50-60 HRC)[○] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○/◎] / Quenched and tempered steel (25 to 35 HRC)[◎] / Quenched and tempered steel (35 to 45 HRC)[◎] / Quenched and tempered steel (45 to 55 HRC)[◎] / High Hardness Steel (50-60 HRC)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Brass cast iron (BsC)[○/◎] / Aluminum Rolled Material (AL)[○/◎] / Aluminum Alloy Casting (AC, ADC)[○/◎] / Magnesium Alloy (MC)[○/◎] / Zinc Alloy Casting (ZDC)[○/◎] / Titanium Alloy (Ti-6Al-4V, etc)[○/◎] / Nickel-based alloy (Inconel, etc.)[◎] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Quenched and tempered steel (35 to 45 HRC)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[◎] / Aluminum Alloy Casting (AC, ADC)[◎] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] / Titanium Alloy (Ti-6Al-4V, etc)[◎] / Nickel-based alloy (Inconel, etc.)[◎] / Thermosetting plastic (bakelite, phenol, etc.)[◎] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[◎] | Cast Iron (FC)[◎] / Ductile Cast Iron (FCD)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Aluminum Alloy Casting (AC, ADC)[◎] / Magnesium Alloy (MC)[◎] / Zinc Alloy Casting (ZDC)[◎] | Cast Iron (FC)[◎] / Ductile Cast Iron (FCD)[◎] / Copper (Cu)[○] / Brass (Bs)[◎] / Brass cast iron (BsC)[◎] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[◎] / Aluminum Alloy Casting (AC, ADC)[◎] / Magnesium Alloy (MC)[◎] / Zinc Alloy Casting (ZDC)[◎] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / High Carbon Steel (C with a content over 0.45%)[◎] / Alloy Steel (SCM)[◎] / Stainless Steel (JIS-SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[◎] / Quenched and tempered steel (35 to 45 HRC)[◎] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | - | - | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Quenched and tempered steel (35 to 45 HRC)[○] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Quenched and tempered steel (35 to 45 HRC)[○] / Quenched and tempered steel (45 to 55 HRC)[○] / High Hardness Steel (50-60 HRC)[○] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Tool Steel (Before SKD Hardening)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] | Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Ductile Cast Iron (FCD)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless Steel (JIS-SUS)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] / Thermosetting plastic (bakelite, phenol, etc.)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Tool Steel (Before SKD Hardening)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Quenched and tempered steel (35 to 45 HRC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] | - | - |

| Tap Type | - | - | Thread cutter | Thread cutter | Thread cutter | - | Hand Tap | - | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | Thread cutter | - | - |

| Hole type | - | - | For through hole / For blind hole | For through hole / For blind hole | For through hole / For blind hole | - | - | - | For through hole / For blind hole | For through hole / For blind hole | For through hole / For blind hole | For through hole / For blind hole | For through hole / For blind hole | For through hole / For blind hole | For blind hole | For through hole / For blind hole | For through hole / For blind hole | For through hole / For blind hole | - | For through hole / For blind hole | For blind hole | For blind hole | For through hole / For blind hole | For through hole / For blind hole | - | For blind hole | For through hole / For blind hole | For blind hole | For blind hole | For blind hole | For blind hole | For blind hole | For blind hole | - | - | - |

| Coating Y/N | - | - | Available | Available | Available | - | - | - | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | Available | - | - |

| Coating Type | - | - | TiAlN | DLC | TiAlN | - | - | - | TiAlN | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) / Other | TiN | TiAlN | TiAlN | TiAlN | TiAlN | TiCN | TiCN | TiN | TiAlN | TiAlN | Nitriding Treatment | Nitriding Treatment | Nitriding Treatment | Nitriding Treatment | Nitriding Treatment | Nitriding Treatment | Nitriding Treatment | Nitriding Treatment | Nitriding Treatment | Nitriding Treatment | Nitriding Treatment | Nitriding Treatment | Other | - | - |

| Overall Length (L)(mm) | 38 ~ 125 | 36 ~ 59 | 57 ~ 115 | 57 ~ 92 | 39 ~ 105 | - | - | 72 | 58 ~ 73 | 48 ~ 74 | 40 | 90 ~ 210 | 60 ~ 120 | 62 ~ 89 | 62 ~ 89 | 60 ~ 120 | 54 ~ 102 | 54 ~ 102 | 90 ~ 200 | 50 ~ 140 | 58 ~ 120 | 58 ~ 120 | 58 ~ 101 | 73 ~ 160 | 73 ~ 84 | 58 ~ 101 | 64 ~ 84 | 39 | 58 ~ 84 | 39 ~ 58 | 39 ~ 64 | 39 | 84 | - | 33 ~ 40 | - |

Loading...

Filter by:

-

Screw Types

- Meter

- Unified

- Whitworth

- Taper for Pipe

- Parallel for Pipes

- Other

-

Screw size (Nominal)

- NO.0-80UNF

- S0.1

- NO.1-72UNF

- NO.1-64UNC

- NO.10-32UNF

- NO.10-24UNC

- NO.12-28UNF

- NO.12-24UNC

- S0.2

- NO.2-64UNF

- NO.2-56UNC

- S0.3

- NO.3-56UNF

- NO.3-48UNC

- S0.4

- NO.4-48UNF

- NO.4-40UNC

- S0.5

- NO.5-44UNF

- NO.5-40UNC

- S0.6

- NO.6-40UNF

- S0.8

- NO.8-36UNF

- NO.8-32UNC

- M1

- S1

- UNC 1

- G1"-3"

- G1/2 5/8

- G1/4

- UNC 1/4

- UNF 1/4

- 1/4-28UNF

- 1/4-20UNC

- G1/8

- M1.2

- S1.2

- M1.4

- S1.4

- M1.6

- M2

- UNC 2

- UNF 2

- M2.2

- M2.5

- M3

- UNC 3

- UNF 3

- G3/8

- M3 - M10

- M3 - M12

- 3.5

- M3.5

- 4

- M4

- UNC 4

- UNF 4

- M5

- G5/8 3/4

- M5 - M12

- UNC 5/16

- UNF 5/16

- 6

- M6

- MF6

- UNC 6

- UNF 6

- 7 execution M3 - M12

- 7.5

- M8

- MF8

- UNC 8

- 9

- M10

- MF10

- UNC 10

- UNF 10

- M12

- MF12

- Mf12

- M12 x 1.5

- M14

- MF14

- M16

- MF16

- Mf16

- M16 x 1.5

- M18

- M20

- MF20

- Mf20

- M20 x 1.5

- M22

- M24

- MF24

- Mf25

- M25 x 1.5

- M27

- MF28

- Mf32

- 1015

- 1020N100M

- 1020N150M

- 06510X28R

- 10154

- 12204

- 12254N100M

- 12254N150M

- 12254N200M

- 16304N100M

- 16304N150M

- 16304N200M

- 16304N250M

- 20305

- 20505N100M

- 20505N150M

- 20505N200M

- 20505N300M

- 20505N350M

- 25506N100M

- 25506N150M

- 25506N200M

- 25506N300M

- 25506N350M

- 32506

- 32506N150M

- 32506N200M

- 32506N300M

- 035083N075M

- 035083N080M

- 040123N100M

- 060163N050M

- 060163N100M

- 060163N125M

- 065103X28G

- 075203N125M

- 075203N150M

- 080153X19G

- 080153X19R

- 080203N050M

- 080203N100M

- 090244N125M

- 090244N175M

- 100254N050M

- 100254N100M

- 100254N150M

- 100254N200M

- 120204X14G

- 120204X14R

- 120304N100M

- 120304N150M

- 120304N200M

- 160264X11G

- 160264X11R

- 160404N150M

- 160404N200M

- 160404N250M

- 200305X11G

- 200305X11R

- 200505N150M

- 200505N200M

- 200505N300M

-

Pitch (P), Number of Threading(mm)

-

Tool Material Type

-

work material

- Low-Carbon Steel (carbon alloy less than 0.25%)

- Medium carbon steel (carbon content 0.25 to 0.45%)

- High Carbon Steel (C with a content over 0.45%)

- Alloy Steel (SCM)

- Stainless Steel (JIS-SUS)

- Quenched and tempered steel (25 to 35 HRC)

- Quenched and tempered steel (35 to 45 HRC)

- Quenched and tempered steel (45 to 55 HRC)

- High Hardness Steel (50-60 HRC)

- Tool Steel (Before SKD Hardening)

- Steel casting (SC)

- Cast Iron (FC)

- Ductile Cast Iron (FCD)

- Copper (Cu)

- Brass (Bs)

- Brass cast iron (BsC)

- Bronze (Pb)

- Aluminum Rolled Material (AL)

- Aluminum Alloy Casting (AC, ADC)

- Magnesium Alloy (MC)

- Zinc Alloy Casting (ZDC)

- Titanium Alloy (Ti-6Al-4V, etc)

- Nickel-based alloy (Inconel, etc.)

- Thermosetting plastic (bakelite, phenol, etc.)

- Thermoplastic plastic (vinyl chloride, nylon, etc.)

-

Tap Type

-

Hole type

-

Coating Y/N

-

Coating Type

-

Overall Length (L)(mm)

Brand

-

- CARMEX (13)

- OSG (6)

- WERA (4)

- YAMAWA MFG (3)

- GUHRING (2)

- SANDVIK (2)

- RUKO (1)

- FEIN (0)

- NS TOOL (0)

- BERNSTEIN AG (0)

- STAHLWILLE (0)

- GEDORE (0)

- HAZET (0)

- REX TOOLS (0)

CAD data type

-

- 2D

- 3D