Vi håller på att översätta vår butik till svenska!

Men eftersom vi har många produkter och sidor tar det tid. Under tiden finns vår produktkatalog på engelska. Tack för ditt tålamod!

- Hardness

- Surface Treatment

- No Surface Treatment

- Surface Treatment Provided

- Black Oxide

- Electroless Nickel Plating

- Shaft Dia. D(mm)

- 10

- 12

- 15

- 20

- 25

- 30

- 35

- 40

- 50

- L(mm)[50-500/0.5mm units]

- LA(mm)[4-150/0.5mm units]

- LB(mm)[4-70/0.5mm units]

- P(mm)

- 6

- 8

- 10

- 12

- 15

- 17

- 20

- 25

- 30

- 35

- 40

- 45

- CAD

- 3D

- Uppskattade leveransdagar

- Alla

- Inom 9 arbetsdagar

- Inom 17 arbetsdagar

- Inom 19 arbetsdagar

- Inom 29 arbetsdagar

Motor shafts / two-sided offset / machining selectable

Artikelnummer:

kandidater hittades.Skiss och specifikationstabell

Dimensional Drawing

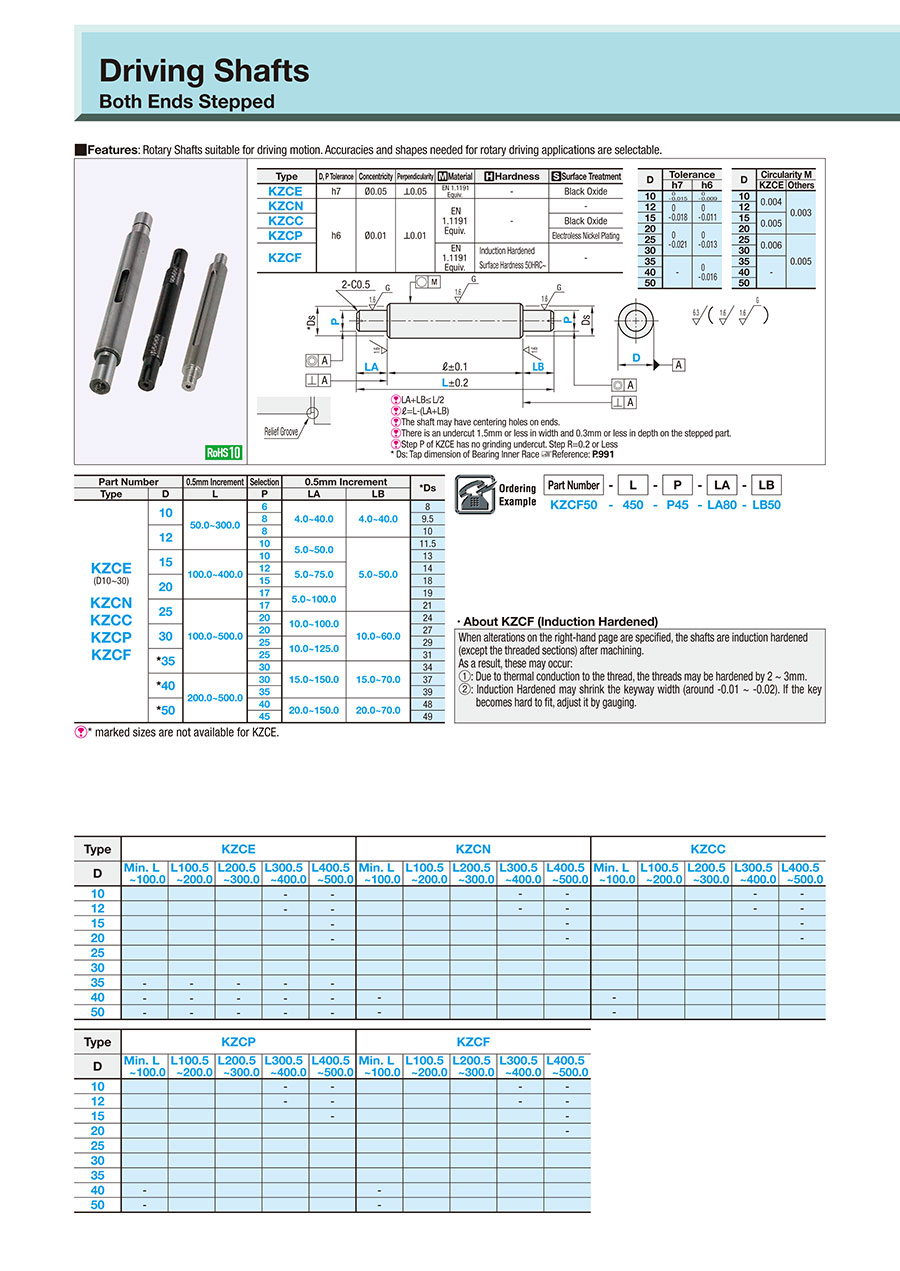

[ ! ]LA+LB ≤ L/2

[ ! ]ℓ = L- (LA+LB)

[!] The shaft may have centering holes on ends.

[!] There is an undercut 1.5 mm or less in width and 0.3 mm or less in depth on the stepped part.

[!] Step P of KZCE has no grinding undercut. Step R = 0.2 or Less

* Ds: Tap dimension of Bearing Inner Race.

| D | Tolerance | |

| h7 | h6 | |

| 10 | 0 -0.015 | 0 -0.009 |

| 12 | 0 -0.018 | 0 -0.011 |

| 15 | ||

| 20 | 0 -0.021 | 0 -0.013 |

| 25 | ||

| 30 | ||

| 35 | — | 0 -0.016 |

| 40 | ||

| 50 | ||

| D | Circularity M | |

| KZCE | Others | |

| 10 | 0.004 | 0.003 |

| 12 | ||

| 15 | 0.005 | |

| 20 | ||

| 25 | 0.006 | 0.005 |

| 30 | ||

| 35 | — | |

| 40 | ||

| 50 | ||

| Type | D, P Tolerance | Concentricity | Perpendicularity | [M] Material | [H]Hardness | [S] Surface Treatment |

| KZCE | h7 | ⌀0.05 | ⊥0.05 | EN 1.1191 Equiv. | — | Black Oxide |

| KZCN | h6 | ⌀0.01 | ⊥0.01 | EN 1.1191 Equiv. | — | — |

| KZCC | Black Oxide | |||||

| KZCP | Electroless Nickel Plating | |||||

| KZCF | EN 1.1191 Equiv. | Induction Hardened | — | |||

| Surface Hardness 50HRC or more |

Specification Table

| Part Number | — | L | — | P | — | LA | — | LB |

| KZCF50 | — | 450 | — | P45 | — | LA80 | — | LB50 |

| Part Number | 0.5 mm Increments | Selection | 0.5 mm Increments | * Ds | ||

| Type | D | L | P | LA | LB | |

| KZCE (D10 to 30) KZCN KZCC KZCP KZCF | 10 | 50.0 to 300.0 | 6 | 4.0 to 40.0 | 4.0 to 40.0 | 8 |

| 8 | 9.5 | |||||

| 12 | 8 | 10 | ||||

| 10 | 5.0 to 50.0 | 5.0 to 50.0 | 11.5 | |||

| 15 | 100.0 to 400.0 | 10 | 13 | |||

| 12 | 5.0 to 75.0 | 14 | ||||

| 20 | 15 | 18 | ||||

| 17 | 5.0 to 100.0 | 19 | ||||

| 25 | 100.0 to 500.0 | 17 | 21 | |||

| 20 | 10.0 to 100.0 | 10.0 to 60.0 | 24 | |||

| 30 | 20 | 27 | ||||

| 25 | 10.0 to 125.0 | 29 | ||||

| * 35 | 25 | 31 | ||||

| 30 | 15.0 to 150.0 | 15.0 to 70.0 | 34 | |||

| * 40 | 200.0 to 500.0 | 30 | 37 | |||

| 35 | 39 | |||||

| * 50 | 40 | 20.0 to 150.0 | 20.0 to 70.0 | 48 | ||

| 45 | 49 | |||||

Alterations

| Part Number | — | L | — | P | — | LA | — | LB | — | (MA, NA, KA, TA, SA, WA, etc.) |

| KZCF40 | — | 300 | — | P30 | — | LA60 | — | LB60 | — | NB12 - TA40 - WB10 - GB20 - AB90 |

| Alterations | Code | Spec. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Left End | Middle | Right End | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Ends  | MA MSA MMA | Left End MC MSC MMC Right End MD MSD MMD | MB MSB MMB | Adds threads at shaft ends. Specify the length of the threads. (Accuracy, coarse or fine threads differ depending on the current ordering code.)

[!] When D,P = M, thread length can be specified.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapped Ends  | NA | — | NB | Adds taps on shaft ends. Select the thread diameter.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Keyway Machining  | KA | KC KD | KB | Adds a keyway. Specify the position and the length of the keyway. Ordering Code KA10-HA30-KB100-HB50 KA, HA, KB, HB, KC, HC, KD, HD = 1 mm Increments [ ! ]3 ≤ HA,HB,HC,HD ≤ 100 [!]When more than 2 keyways are added, the tolerances may shift by up to 0.2°. [!] Specify the keyway position more than 2 mm away from the stepped part. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Keyway Machining + Set Screw Flat  | ZA | ZC ZD | ZB | Adds a flat at any designated angle based on the keyways. Specify the position and the length for each keyway, and the angle for the set screw flats. ·Specification Code

[!] The length of each set screw flat is the same as that of each keyway. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Retaining Ring Groove  | TA | TC TD | TB | Adds a retaining ring groove. Specify the position of a retaining ring groove. Ordering Code TA10-TB10 TA, TB = 1 mm Increments 4 ≤ TA (TB) ≤ LA (LB)-3 [!] Retaining rings are included. P = 6,8: Retaining Ring Type E P ≥ 10, D ≥ 10: Retaining Ring Type C

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wrench Flats  | SA | SD | SB | Adds wrench flats. Specify the position of a wrench flat.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 Set Screw Flats (Angle Specified)  | WA | WC | WB | Adds a flat at any designated angle besides the datum plane 0°. ·Specification Code

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tolerance Change  | PJ (js6) PK (k6) | Changes the tolerance of P Dimension of the stepped part to js6 or k6. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

·About KZCF (Induction Hardened)

When alterations on the above are specified,

the shafts are induction hardened after machining. (Except the threaded sections)

As a result, these may occur:

(1): Due to thermal conduction to the thread, the threads may be hardened by 2 to 3 mm. (2): Induction Hardened may shrink the keyway width (Around -0.01 to -0.02)

If the key becomes hard to fit, adjust it by gauging.

Artikelnummerlista

| Artikelnummer |

|---|

Enhetspris (exklusive MOMS)(Enhetspris inklusive MOMS) | Standardavsändningsdatum |

|---|

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 9 arbetsdagar |

- ( - ) | 9 arbetsdagar |

- ( - ) | 9 arbetsdagar |

- ( - ) | 9 arbetsdagar |

- ( - ) | 9 arbetsdagar |

- ( - ) | 9 arbetsdagar |

- ( - ) | 29 arbetsdagar |

- ( - ) | 29 arbetsdagar |

- ( - ) | 29 arbetsdagar |

- ( - ) | 29 arbetsdagar |

- ( - ) | 29 arbetsdagar |

- ( - ) | 29 arbetsdagar |

- ( - ) | 29 arbetsdagar |

- ( - ) | 29 arbetsdagar |

- ( - ) | 29 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 17 arbetsdagar |

- ( - ) | 19 arbetsdagar |

- ( - ) | 19 arbetsdagar |

- ( - ) | 19 arbetsdagar |

- ( - ) | 19 arbetsdagar |

- ( - ) | 19 arbetsdagar |

- ( - ) | 19 arbetsdagar |

- ( - ) | 19 arbetsdagar |

- ( - ) | 19 arbetsdagar |

- ( - ) | 19 arbetsdagar |

Detaljerad information

Grundläggande information

Skiss och specifikationer

Specifications/Overview

■Selection of Driving Shaft

In selecting a driving shaft, select the basic shape and size from the specification table, then select necessary alterations such as thread machining, keyway addition etc.

[Selection Example of Part Number]

·Alteration Selection: A retaining ring groove, two set screw flats at 0° and 90° and a tap

[App. Example]