- Thickness T(mm)

- 5

- 6

- 8

- 10

- 12

- 15

- 20

- 25

- 30

- 35

- 40

- Length A(mm)[25-500/1mm units]

- Width B(mm)

- 25

- 40

- 60

- 80

- 100

- 125

- 150

- 160

- 200

- Type

- CAD

- 2D

- Uppskattade leveransdagar

- Alla

- Inom 9 arbetsdagar

Ytterligare alternativ

- Change Width (B Dimension) [BC](Cut the B Dimension)(mm)[126-149/1mm units][41-59/1mm units][151-159/1mm units][161-199/1mm units][81-99/1mm units][26-39/1mm units][101-124/1mm units][61-79/1mm units]

- Circumference Chamfering

- Change Plate Thickness [TC](Cut T Dimension)(mm)

- 7

- 9

- 11

- 13

- 14

- 16

- 17

- 18

- 19

- 21

- 22

- 23

- 24

- 26

- 27

- 28

- 29

- 31

- 32

- 33

- 34

- 36

- 37

- 38

- 39

- Corner Cut [CCA](Cut Corner of A)(mm)[1-10/1mm units]

- Corner Cut [CCB](Cut Corner of B)(mm)[1-10/1mm units]

- Corner Cut [CCC](Cut Corner of C)(mm)[1-10/1mm units]

- Corner Cut [CCD](Cut Corner of D)(mm)[1-10/1mm units]

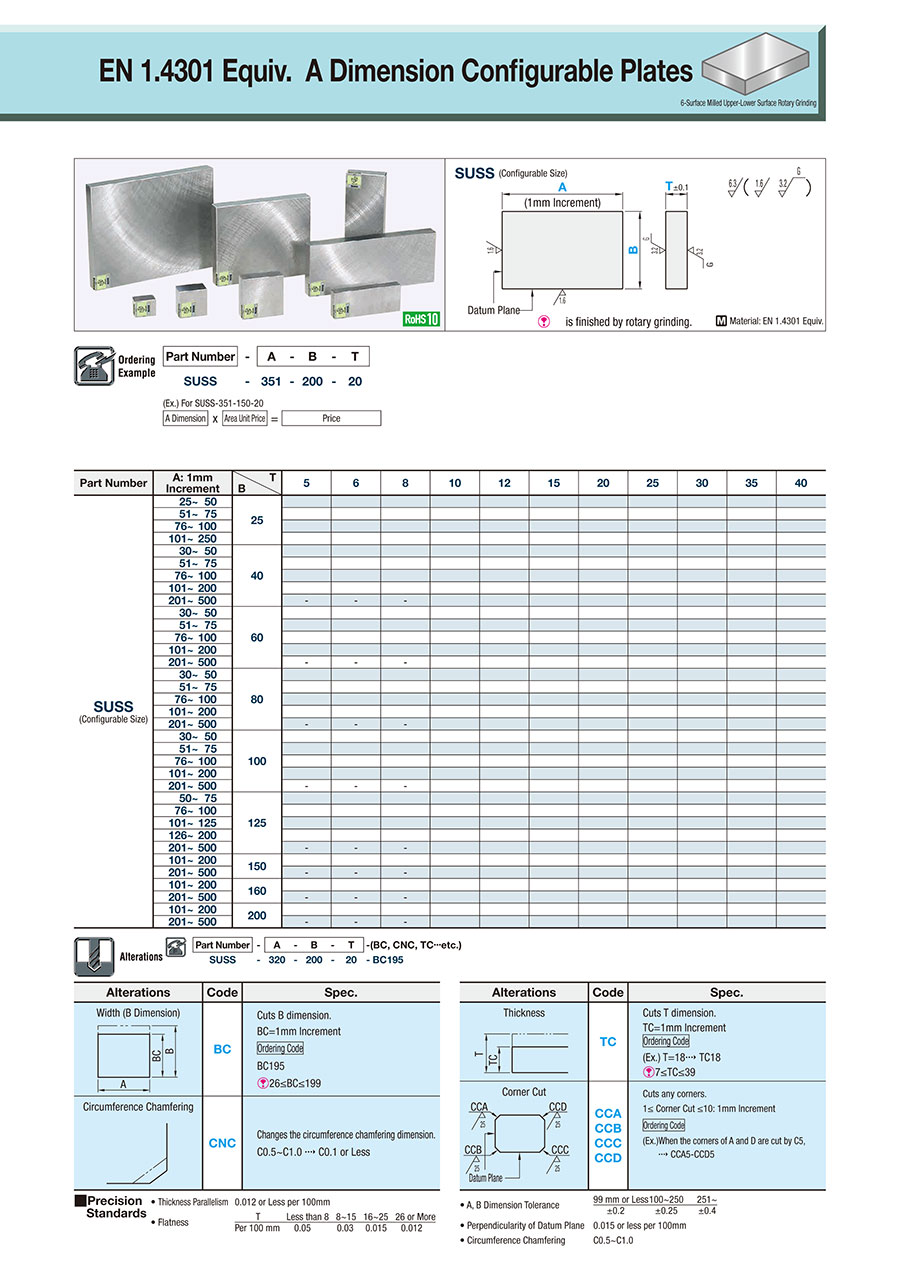

Metal plates / flat ground surface / A configurable / EN 1.4301 Equiv.

Klicka bilden för att visa förstorad bild

Artikelnummer:

Skiss och specifikationstabell

Dimensional Drawing

[M]Material: EN 1.4301 Equiv. (After hot rolling, it has undergone heat treatment, acid pickling, or treated in a similar manner)

Specification Table

| Part Number | — | A | — | B | — | T |

| SUSS | — | 351 | — | 200 | — | 20 |

| Part Number | Finish Method | A, B Dimension Tolerance | Thickness Parallelism (per 100 mm) | Flatness (per 100 mm) | Perpendicularity of Datum Plane (per 100 mm) | Circumference Chamfering | |||||

| Up to 99 mm | 100 to 250 | 251 or more | Up to T7 | T8 to 15 | T16 to 25 | T26 or more | |||||

| SUSS | Side Milled Plate Thickness Surface Rotary Ground | ±0.2 mm | ±0.25 | ±0.4 | 0.012 | 0.05 | 0.03 | 0.015 | 0.012 | 0.015 | C0.5 to C1.0 |

Alterations

| Part Number | — | A | — | B | — | T | — | (BC, CNC, TC, etc.) |

| SUSS | — | 320 | — | 200 | — | 20 | — | BC195 |

| Alterations | Code | Spec. | Alterations | Code | Spec. | |

Width (B Dimension) | BC | Cuts B dimension. BC = 1 mm Increments Ordering Code BC195 [ ! ]26 ≤ BC ≤ 199 | Thickness | TC | Cuts T dimension. TC = 1 mm Increments Ordering Code (Example) When T = 18, TC18 [ ! ]7 ≤ TC ≤ 39 | |

Circumference Chamfering | CNC | Changes the circumference chamfering dimension. C0.5 to C1.0 >> C0.1 or Less | Corner Cut | CCA CCB CCC CCD | Any corner can be cut. 1 ≤ Corner Cut ≤ 10 1 mm Increments Ordering Code Example: When the corners of A and D are cut by C5 →CCA5-CCD5 |

Detaljerad information

Grundläggande information

[Features] Rotating polishing plate (stainless steel) with custom linear dimensions.

Skiss och specifikationer

Specifications/Overview

| ● Thickness Parallelism | 0.012 or Less per 100 mm |

| ● Flatness | T: Less than 8, 8 to 15, 16 to 25, 26 or More 0.05, 0.03, 0.015, 0.012 per 100 mm |

| ● A, B Dimension Tolerance | 99 mm or Less, 100 to 250, 251 or More ±0.2 ±0.25 ±0.4 |

| ● Perpendicularity of Datum Plane | 0.015 or Less per 100 mm |

| ● Circumference Chamfering | C0.5 to C1.0 |

General Information - Metal Ingots

Selection details of flat steels/plates (metal)

- Material: aluminum, steel, tool steel, pre-hardened steel, stainless steel (stainless steel), copper, titanium

- Surface treatment: milled, front-polished, flat-polished

- Heat treatment: annealed, normal annealed, pre-hardened, tempered, half hard, quarter hard

- Length [A]: 6 to 3000 mm in 0.01 mm increments

- Width [B]: 6 to 1500 mm in 0.01 mm increments

- Thickness [T]: 1.5 to 100 mm in 0.01 mm increments

- Parallelism: up to 0.01/100 mm

- Evenness: up to 0.01/100 mm

- Perpendicularity: up to 0.02/100 mm

Description/Basics

The metal plates from MISUMI are semi-finished products and are often used in the industry for further processing.

These can be selected in the MISUMI online shop in different versions. The machining of the lateral surfaces, or rolled, milled or ground at the top and the bottom, is available for the metal plate. The metal plates are available in various tolerances. This usually depends on the respective surface machining. This allows you to configure the MISUMI metal plates to suit your needs and use them as a semi-finished product for further processing. A customized metal block or metal plate can help to reduce the number of work steps in your further processing of the metal plate.

The metal plates can therefore be used well as semi-finished products for further processing, or often serve as a base plate for substructures, as well as column guide frames.

An overview of the different metal plates can be found in the PDF Metal Plate Overview.

You can find other shapes and materials of the semi-finished products by following this link.

MISUMI also offers the service to manufacture metal plates according to your needs with meviy by uploading CAD data.

Aluminum Plate

The aluminum plate as a blank or raw material from MISUMI is light compared to other materials, but stable and shock resistant. Therefore, the material aluminum is very often used as a Aluminium Extrusions in plant and mechanical engineering.

Aluminum plates exhibit good corrosion resistance despite the lack of surface treatment. In principle, aluminum forms an oxide layer that prevents further corrosion. Aluminum plates are very good for further processing.

Steel Plate

Steel plates made of structural steel are inexpensive in terms of their ratio and also economical due to their good workability.

The steel plate offers high strength and density. Steel has long been a very common material, so there are many types of steel suitable for different technical requirements.

Alloy tool steel has a higher temperature resistance, resistance, and hardness than usual structural steel. Another major advantage of this steel plate is the possibility of hardening and remuneration of the material.

One disadvantage of steel plates is the rather poor corrosion resistance. Without a subsequent surface treatment, steel tends to quickly corrode.

Stainless Steel Plate

The MISUMI stainless steel plates have good to very good corrosion resistance, which makes the material durable. MISUMI offers various stainless steel plates for a wide variety of requirements in plant and mechanical engineering.

The surface of stainless steel can be visually refined by sanding or polishing. Stainless steel plates have good temperature resistance, but stainless steel can stain at high temperatures (tempering colour). This should be taken into account for welding joints.

Stainless steels with chrome-nickel content have an antibacterial effect and offer a poor substrate for germs when polished, which also makes the stainless steel plate hygienic.

Copper Plate/Brass Plate

The copper plate has very good thermal conductivity and electrical conductivity. This represents a special feature for other materials. Copper plates also have good corrosion resistance and are resistant.

MISUMI offers various copper alloys in its product range. The most commonly used copper is cold-solidified copper due to its good electrical conductivity and thermal conductivity.

Another variant of the copper plate is MISUMI made of oxygen-free copper, which is also known as pure copper. Oxygen-free copper has good resistance to hydrogen embrittlement and is often used in the electrical industry.

Chrome copper plates offer good mechanical strength and abrasion resistance at high temperatures.

The brass plate, on the other hand, offers high strength and ductility. Therefore, brass permits plastic deformation before the material has a fatigue fracture.

Titanium Plate

Titanium plates from MISUMI can be referred to as pure titanium.

The titanium plate is light, but it has a high strength and very high corrosion resistance. Titanium plates also have very good biocompatibility. Since the titanium plates are also biologically compatible, this material is frequently represented in medical technology. Due to its low weight and high strength, titanium is also often used in lightweight construction such as aerospace and aviation. The possible application spectrum of titanium is large. However, titanium plates are usually only used if the properties such as strength of aluminum, for example, are no longer sufficient. The reason for this is that titanium is more cost-intensive in comparison, since production causes a high energy consumption. However, the combination of the good properties of titanium is required for many applications and applications.

Additional properties of the various materials can be found in the PDF of the Metal Plate Properties.

On-demand Manufacturing

With meviy, MISUMI also offers to manufacture metal plates and sheet metal according to your wishes. Simply upload the CAD data.

Industrial Applications